Custom Extension Spring Manufacturer

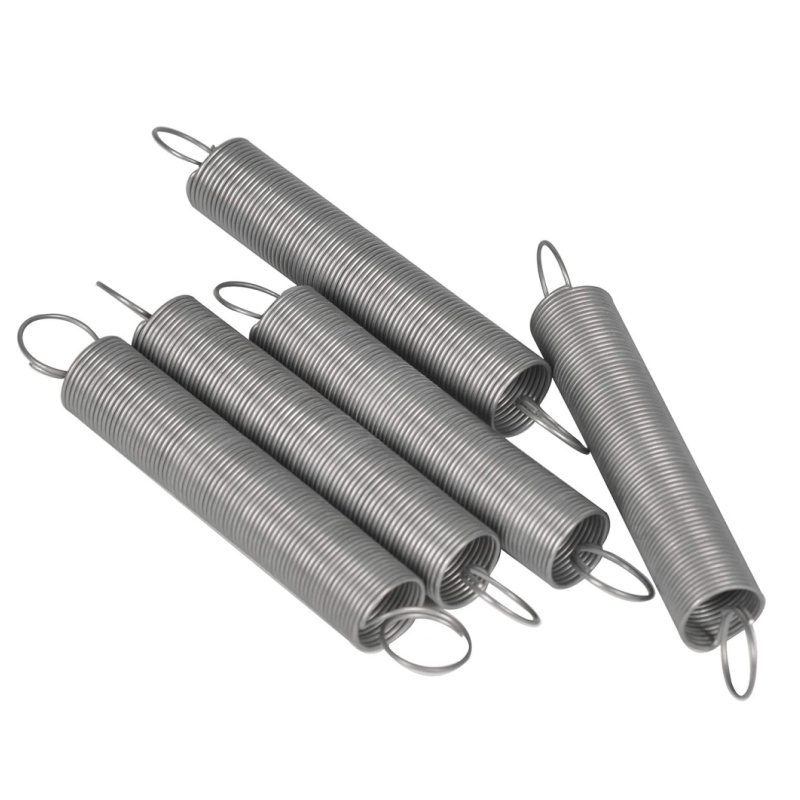

We specialize in delivering durable, high-performance extension springs,precision, and reliability in the springs, with fast delivery times and customization options.

Custom Any Extension Springs for Your Project

Zigoal offers full capabilities in custom extension springs tailored to your project needs. We can manufacture according to your specific designs, dimensions, material types, surface finishes, and more too meet your specific needs.

Our Custom Extension springs Capability:

- .007 to .394Inches(10mm) In Wire Diameter

- RoundWire, Rectangular Wire, Square Wire & Special-Section Wire

- Custom Springs Manufactured to Meet Your Specific Needs

- Rapid prototyping and full-scale production

Contact Us Today to Discuss Your Custom Extension Spring Needs!

Why choose our Extension Spings?

High Tensile Strength

Built for durability and resilience in demanding conditions

Precision Engineered

Ensures exact performance with tight tolerances

Corrosion Resistance

Protective coating for harsh environments

Extended Lifecycle

Designed to resist fatigue and last longer.

Explore Our Custom Extension Spring Types for Industry

Zigoal is a Custom Extension Sping manufacturing, We’re provides Helical Extension Springs, Double Loop Extension Springs, Trampoline Springs, Drawbar Springs, Variable Pitch Extension Springs, and Conical Extension Springs. Our high-quality springs cater to the Automotive, Electronics Manufacturing, and Medical Equipment sectors, providing industry-leading versatility, durability, and precision-engineered solutions for diverse applications.

Helical Extension Springs

Helical extension springs are tightly wound coils that extend under force, commonly used in household items and industrial machinery. Features: Available with various hook ends for easy attachment. Applications: Garage doors, levers, scales.

Double Loop Extension Springs

Double loop extension springs have two coils per end, ensuring secure attachment. Features: Enhanced durability, ideal for strong attachment needs. Applications: Automotive seats, heavy-duty machinery.

Trampoline Springs

Trampoline Springs: designed for variable resistance, providing precise load control. Features: Balancing support, durable under variable forces. Applications: Precision devices, load balancing systems.

Drawbar Springs

Drawbar springs feature metal bars at each end, limiting extension when pulled, also called mooring springs. Features: Controlled movement, supports higher load capacity. Applications: Large gates, industrial machinery.

Variable Pitch Extension Springs

Variable pitch springs have uneven coil spacing, providing non-linear load response. Features: Suitable for applications needing varied tension resistance. Applications: Precision instruments, specialized mechanical assemblies.

Conical Extension Springs

Conical springs feature variable coil diameter, also called tapered extension springs. Features: Higher force capacity, reduced stress on attachment points, ideal for tight spaces. Applications: Aerospace, automotive suspension.

Know About Custom Extension Spring

Custom Extension Spring Design

Load requirements, deflection limits, wire diameter, coil diameter, free length, end hook configurations, loop configurations, tension, stress distribution, fatigue life, spring rate, tolerances, performance specifications.

Load Requirements: Defines the maximum force the spring must support without failure.

Deflection Limits: Measures how much the spring can stretch or compress under load.

Wire Diameter: Thickness of the wire used in the spring, crucial for determining strength.

Coil Diameter: Outer diameter of the spring coil, affecting tension and space.

Free Length: The unstressed length of the spring, important for installation fit.

End Hooks and Loops: Components at the spring’s ends that allow attachment to other parts.

Tension and Stress Distribution: Balancing force through the spring to prevent deformation or failure.

Fatigue Life: The number of cycles a spring can endure before failure due to repeated stress.

Spring Rate: The stiffness of the spring, determining how much force is required for deflection.

Tolerances: Allowable variation in spring dimensions during manufacturing.

At Zigoal, we understand that the choice of material is critical in spring manufacturing. Different extension spring materials offer unique properties, making them suitable for specific applications. Our extension spring experts will assist you in selecting the ideal material for your custom made extension springs.

Carbon Steel: Commonly used due to its strength, affordability, and availability.

Stainless Steel: Provides corrosion resistance and durability in harsh environments.

Alloy Steel: Offers enhanced performance under high stress and temperature conditions.

Phosphor Bronze: Known for its electrical conductivity and corrosion resistance, ideal for electrical components.

Beryllium Copper: Highly conductive with good fatigue strength, often used in precision instruments.

Inconel: A high-performance alloy resistant to extreme temperatures and corrosion, suitable for aerospace and industrial applications.

Music Wire: High-carbon steel wire known for its excellent fatigue life and high tensile strength.

Custom Extension Spring Finishings

Zinc Plating: a popular finish that provides corrosion resistance and an attractive appearance.

Electropolishing: a process that enhances surface smoothness, reduces friction, and increases corrosion resistance.

Powder Coating: A durable, colored finish that adds an extra layer of protection against wear and tear.

Passivation: A chemical treatment that removes contaminants and improves the spring’s resistance to oxidation.

Phosphate Coating: Enhances lubrication properties and corrosion resistance, ideal for industrial applications.

Nickel Plating: Offers a shiny, decorative appearance while providing excellent resistance to corrosion.

Teflon Coating: Creates a low-friction surface, making it ideal for applications requiring smooth movement.

Black Oxide Finish: Improves aesthetics while providing a moderate level of corrosion resistance.

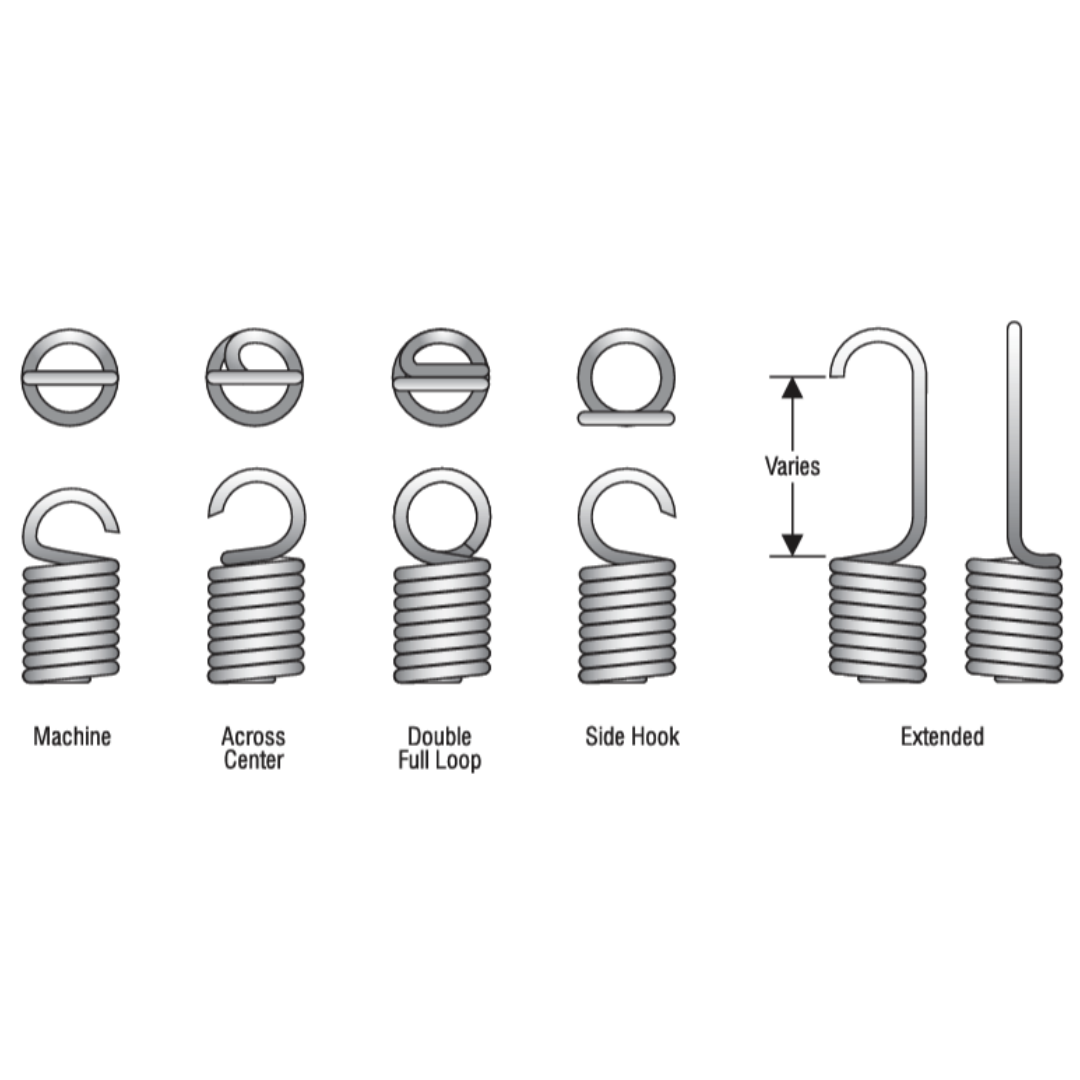

Extension springs, integral to numerous mechanical applications, are equipped with various types of ends or hooks.

Machine Hooks: Standard end type providing durability and ease of attachment.

Crossover Hooks: Offers better load distribution, reducing stress on the spring’s end.

Extended Hooks:Longer hooks designed for specific attachment requirements and increased flexibility.

Double Loop Ends: Provides a stronger attachment point, suitable for high-stress applications.

V-Hooks:V-shaped ends that ensure a secure fit in specialized installations.

Custom Bent Ends: Tailored designs to match specific application needs, enhancing spring functionality.

Threaded Inserts: Facilitates a secure and adjustable attachment method for precise adjustments.

Extension Spring Hook Types for Optimal Performance

Custom Extension Spring Applications

Custom extension springs power diverse applications, from automotive brakes and throttles, aerospace landing gear, and medical devices to industrial machinery, consumer products, agricultural equipment, electronics, and construction tools, ensuring precision and durability across industries solutions.

Automotive Industry

Custom extension springs play a crucial role in vehicle systems, ensuring components return to their original positions and manage dynamic loads.

Throttle Return Springs: Used in throttle mechanisms to return the throttle valve to a closed position after acceleration.

Brake Springs: Assist in returning brake components, like brake shoes or calipers, to their rest position.

Door Springs: Springs are used in door handles, latches, or trunk releases to provide smooth return actions.

Suspension Spring: Provide balancing tension in adjustable suspension parts.

Fuel Injector Systems: Help in controlling fuel flow by managing tension within injectors.

Aerospace Industry

Custom extension springs must meet high reliability and stringent material standards in aerospace applications, given the extreme conditions and safety requirements.

Landing Gear Retraction Systems: springs are used to maintain tension in belts or chains for material transport.

Cockpit Controls: Provide tension in levers and other control mechanisms.

Aerospace Locking Mechanisms: Ensure that components such as doors or hatches return to a locked position.

Actuator Mechanisms: Springs manage the movement of actuators in wing flaps or rudders.

Satellite Deployment Mechanisms: In space applications, springs help control deployment of solar panels or antennae.

Medical Devices

Mmedical technology, custom extension springs must often meet biocompatibility standards and provide precise, controlled movements.

Surgical: Springs ensure instruments like scissors or clamps return to their rest position.

Drug Delivery Systems: Springs manage the controlled release of medication in infusion pumps or injectors.

Hospital Beds: Springs help adjust bed positioning and support patient movement.

Prosthetic Devices: Provide flexibility and controlled motion in joints of prosthetics.

Rehabilitation Devices: Used in devices for physical therapy to offer resistance or return motion.

Consumer Products

In everyday products, custom extension springs offer utility in a wide variety of common devices that require tension or controlled movements.

Garage Doors: Springs are essential for counterbalancing the weight of doors and enabling smooth opening and closing.

Toys and Gadgets: Springs enable movement in toys, gadgets, and retractable parts.

Appliance Doors: Assist in the smooth opening and closing of doors in ovens, dishwashers, or washing machines.

Exercise Equipment: Provide tension and resistance in equipment like rowing machines or weight trainers.

Clothes Pegs: Enable the gripping function through tension in the peg’s mechanism.

Electronics and Electrical Equipment

In electronics, precision and miniaturization are critical. Custom extension springs are often designed to fit in small, intricate mechanisms.

Battery Contacts: Provide consistent contact pressure for batteries in portable devices.

Switch Mechanisms: Return switches or buttons to their original position after being pressed.

Reel and Retractable Cords: Help retract power or data cables for storage and protection.

Circuit Breakers: Maintain tension in mechanical components that control electrical circuits.

Printers and Scanners: Springs control the movement and return of mechanical parts like rollers or print heads.

Rapid Prototyping for Custom Extension Springs

Rapid prototyping is at the core of Zigoal’s manufacturing capabilities, focused on transforming concepts into precise, tangible products efficiently.

- Speedy Development: Our extension springs are designed to meet application requirements swiftly, cutting lead times to deliver prototypes within days.

- Cutting-Edge Design: Utilizing advanced spring design techniques such as CAD and 3D printing, we ensure the versatility of tension spring designs to meet load requirements.

- Cost-Effective Production: The design process minimizes waste while adhering to load requirements, keeping projects within budget.

- Client Collaboration: We understand spring needs closely and collaborate to provide tailored spring solutions.

- Quality Assurance: With rigorous testing protocols for each tension spring, our process guarantees the highest quality.

- Market-Ready Prototypes: Our prototypes are designed for practical application and initial tension testing, easing the transition to mass production.

Why Zigoal is Trusted by 1000+ Clients?

One-stop Custom Solutions

The ability to customize springs to specific requirements is crucial. As an engineer, ensuring that the springs fit the exact specifications of the project is paramount.

Quality and Precision

Quality and precision in manufacturing are crucial for durable, high-performance springs.

Robust Supply Chain Management

Efficient supply chain management ensures timely delivery and consistent product availability, critical for project timelines.

Strict Quality Control

- Dimensional Inspection: Precise measurements ensure springs meet specified dimensions and tolerance levels.

- Material Testing: Verifies material properties like tensile strength, hardness, and composition to ensure compliance with required specifications.

- Load Testing: Confirms the correct force output by testing springs under specified loads and displacements.

- Fatigue Testing: Simulates long-term usage by testing springs through multiple cycles, predicting lifespan and performance.

- Environmental Testing: Springs for harsh conditions undergo additional tests, including corrosion resistance and temperature cycling, to ensure durability.

Certified Quality

Service Global. Precision Engineering. Quality Guaranteed. High Durability. No Failure. Optimal Performance.

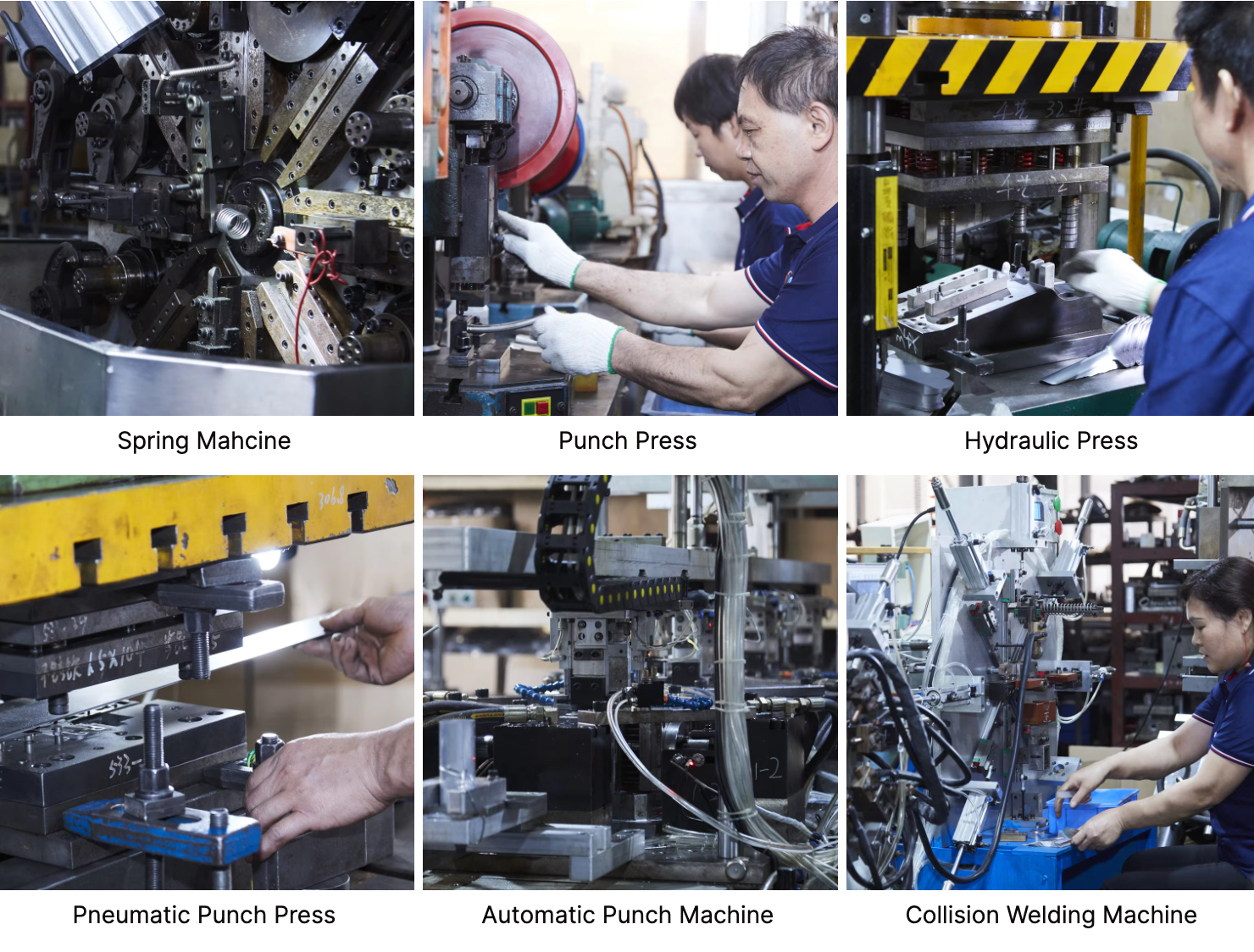

Extension Spring Manufacturing Process

Step-by-Step Overview of the Spring Manufacturing Process

Spring Winding

End Shaping

Heat Treating

Cleaning

Surface Treatment

Testing

Simple 3 Steps to Custom Spring

Send Your Inquiry

Fill out our contact form with your details and attach relevant drawings or specifications for your custom springs

Sample and Production

We create a prototype of your customized spring for approval and initiate manufacturing upon your confirmation that it meets all specifications

Parts are Shipped!

Zigoal's state-of-the-art digital manufacturing process ensures rapid production with turnaround times as fast as few days

Our Happy Clients Say

At Zigoal, we pride ourselves on building strong, lasting relationships with our diverse clientele. Our journey over the years has been marked by successful collaborations with a multitude of industries, each with unique demands and high standards.

Working with Zigoal has been a breeze. Their one-stop custom spring solutions have improved our machinery’s efficiency,their expertise and quality are unmatched. And Lily from their team is a pleasure to collaborate with.

In my role as Procurement Director at XYZ Tech Solutions, I’ve partnered with Zigoal for years, and their custom springs have always exceeded our expectations. Their expertise and quality are unmatched.

As a Robotics Strategic Project Manager at Global Robotics, I can confidently say that Zigoal’s compression springs have been an integral part of our robotic systems. Peter’s team provided tailored solutions that have been crucial to our success.

Frequently Asked Questions

Clearing the Confusion and Enhancing Customer Satisfaction Efficiency about Custom Extension Spring Manufacturer in China. Feel free to reach out to our professional team for expert guidance.

The choice of material depends on the application. Common materials include carbonsteel, stainless steel, and alloy steel. Stainless steel is ideal for corrosion resistance,while carbon steel is cost-effective for general use. Let us know your application, andwe can recommend the best material.

Lead times vary depending on the complexity and quantity of the springs ordered. Forstandard extension springs, the lead time takes 7-10days, whereas custom springsmay take longer due to design and tooling reguirements. We will provide anestimated lead time once we review your project specifications.

The minimum order guantity depends on the specific requirements of your project.We can accommodate small prototype orders as well as larger production runs. Feelfree to discuss your project with us to determine the best solution.

The minimum order guantity depends on the specific requirements of your project.We can accommodate small prototype orders as well as larger production runs. Feelfree to discuss your project with us to determine the best solution.

Yes, we offer prototype and sample services for custom extension spring designs.This allows you to test the springs before committing to a larger order. Please contactus to discuss sample production options.

Hi there, I am Annie Lin, the key account manager of Zigoal. Contact us to get a free quote and more expertise about custom metal springs and wire forms. Your project will meet a right solution with us.