Zigoal Spring Service

Our one-stop service for custom spring & wire forms covers every stage of our cooperation, from before-sales consultation to after-sales support.

Custom Spring Manufacturing

Custom Springs At Zigoal, we specialise in the art of custom springs manufacturing. Our dedicated team of experts excels in bespoke spring design to cater to your unique requirements. With decades of experience as custom spring manufacturers, we’ve honed our craft to offer top-notch solutions.

- Sizes:

Round wire .007″ (.18mm) – 0.394″ (10mm) Flat Wire / Strip Thickness .003″ (.076mm) – .078″ (2.0mm) Flat Wire / Strip Width up to 2.50″ (63.5mm) - Component Types:

Custom Compression Springs,Custom Extension Springs,Custom Torsion Springs,Custom Magazine Springs,Constant Force Springs,Custom Wireforms, Custom Fourslide Stampings

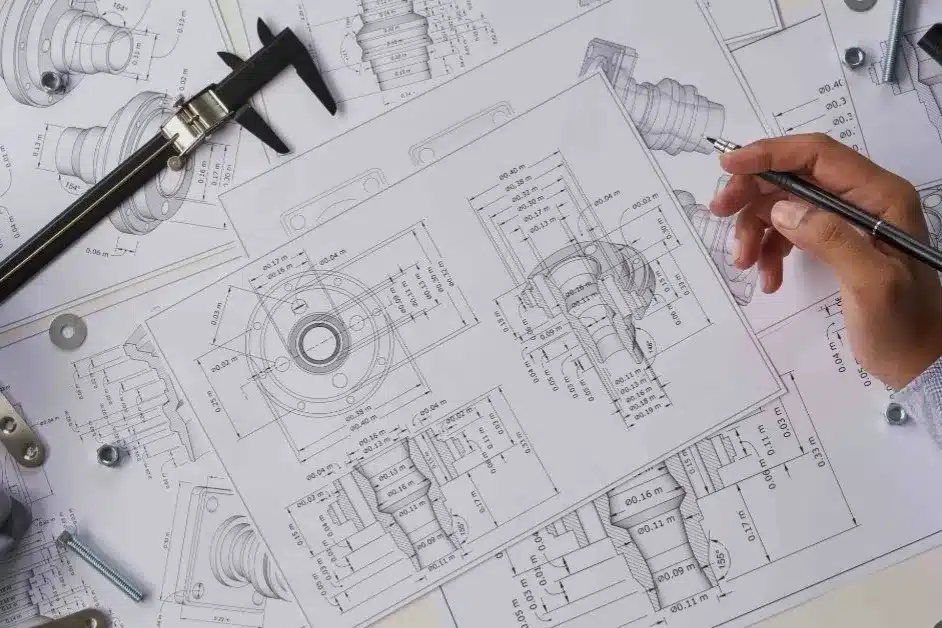

Custom Spring Engineering

At Zigoal, we provide expert engineering solutions for custom springs. Whether you’re designing a new component or improving an existing one, our team delivers tailored support throughout the process.

Custom Design and Optimization

Using advanced design software, we evaluate your spring’s functionality, manufacturability, and performance. Our engineers optimize designs to reduce stress, improve durability, and ensure precise tolerances.Advanced Tools and Expertise

We use 3D modeling and finite element analysis (FEA) to ensure accurate designs that meet your specifications. We can provide prototypes quickly and adjust designs based on real-world simulations.Problem Solving and Material Selection

Our team offers solutions for improving existing designs and selects materials that withstand your application’s demands, whether it’s high-stress environments or extreme temperatures.

Rapid Prototyping

Rapid prototyping is at the core of Zigoal’s manufacturing prowess. It’s about turning concepts into tangible products with speed and precision. Here’s a concise overview:

- Speedy Development: We cut lead times, delivering functional prototypes in days, not months.

- Cutting-Edge Tech: We employ 3D printing and CAD for intricate designs and material versatility.

- Cost-Effective: Our process minimizes waste and keeps projects on budget.

- Client Collaboration: We work closely with you, ensuring a tailored solution.

- Quality Assurance: Stringent testing guarantees top-notch quality.

- Market-Ready: Our prototypes are functional for market testing, easing the transition to mass production.

Material You Can Choose for Your Custom Springs

Comprehensive Material Range

We offer a wide variety of materials, including high-carbon steel, stainless steel, alloys, and non-ferrous metals like brass and titanium. These options ensure optimal performance in terms of strength, corrosion resistance, and heat tolerance.Tailored to Application

Our engineers help you select materials based on the environmental, mechanical, and operational conditions your spring will face, ensuring maximum lifespan and reliability.Specialty Materials for Key Industries

For industries like aerospace, automotive, and medical, we provide high-performance materials such as Inconel, Hastelloy, and Elgiloy, designed for strength and resistance to extreme conditions.

Comprehensive Finishing

Zigoal provides a diverse selection of custom surface finishes to enhance the protection, durability, and aesthetic appeal of your custom metal stamping. Each surface finish offers unique benefits tailored to specific applications and environmental conditions. Our surface treatment options include:

- Passivation

- Painting

- Titanium Nitride Coating

- Heat Treatment

- Anodizing

- Zinc Plating

- Chrome Plating

- Nickel Plating

- Powder Coating

- Black oxide

If you have specific requirements for surface finishes,please don’t hesitate to reach out to us!

Tool And Die

For complex and highly specialized spring designs, precision tooling is essential to ensure dimensional accuracy and performance.

Custom Tooling for Unique Designs

Our in-house tool and die department is equipped with advanced CNC machines and skilled engineers capable of designing and producing the custom dies and molds needed for your unique spring designs. Whether you require intricate wire forms, torsion springs, or specialized compression springs, our tools are made to your exact specifications.

High-Precision Machining

We utilize state-of-the-art CNC machining and wire EDM (Electrical Discharge Machining) to create dies that guarantee dimensional accuracy and repeatability. This high level of precision ensures that each spring produced maintains consistent quality across large production runs, reducing variability and ensuring performance reliability.

Unlock Cost Savings and Quality

Don’t compromise on quality or budget. Contact us now to find out how our custom springs and wire forms can save you money while maintaining exceptional quality

Simple 3 Steps to Custom Spring

Send Your Inquiry

Fill out our contact form with your details and attach relevant drawings or specifications for your custom springs

Sample and Production

We create a prototype of your customized spring for approval and initiate manufacturing upon your confirmation that it meets all specifications

Parts are Shipped!

Zigoal's state-of-the-art digital manufacturing process ensures rapid production with turnaround times as fast as few days

Compression Spring Manufacturing Process

When it comes to spring manufacturing, Zigoal leverages cutting-edge technology and expert craftsmanship to ensure precision and consistency in every step of the process.

Coiling

Heat Treating

Cleaning

Surface Treatment

Testing

Packaging

Hi there, I am Annie Lin, the key account manager of Zigoal. Contact us to get a free quote and more expertise about custom metal springs and wire forms. Your project will meet a right solution with us.