Custom Torsion Springs Manufacturer

Delivering high-quality, durable torsion springs for industrial, automotive, and aerospace applications.

Why choose our Torsion Springs?

High Fatigue Resistance

Offer lasting performance, resisting fatigue under continuous stress

Precision Tolerance

Crafted with tight tolerances for accurate, consistent performance in precision applications

Corrosion-Resistant Coating

Advanced anti-corrosion finishes enhance our custom torsion springs’ durability in harsh environments

High-strength Materials

Ensuring longevity and resilience in demanding conditions

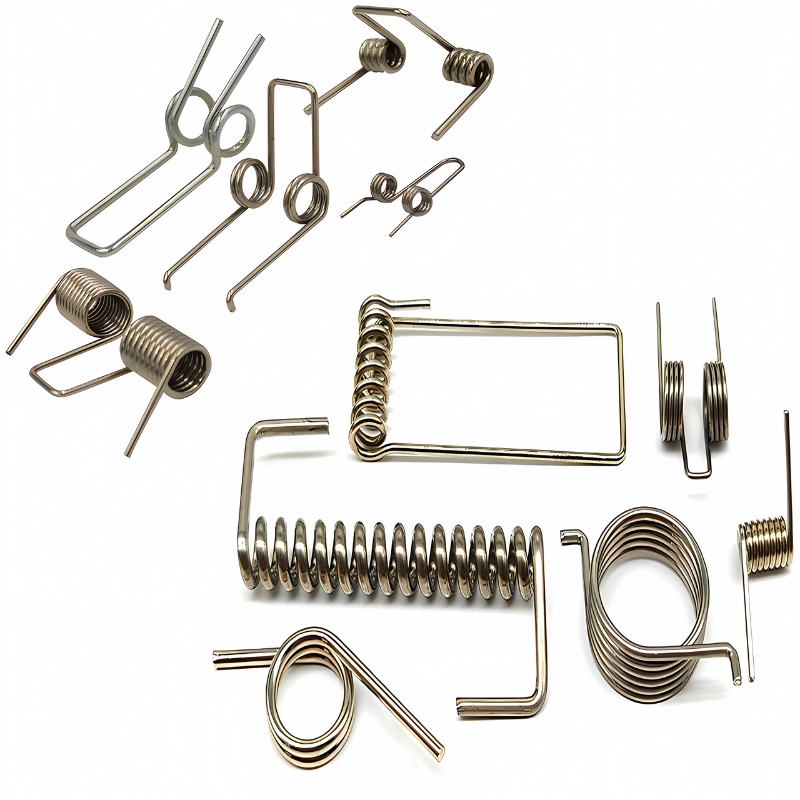

Explore Our Custom Torsion Spring Types for Industry

Zigoal is a Custom Torsion Spring manufacturer. We provide Torsion Helical Springs, Single Torsion Springs, Double Torsion Springs, Barrel Torsion Springs, Flat Spiral Torsion Springs, Constant Force Torsion Springs and more. Our high-quality torsion springs cater to the Automotive, Electronics Manufacturing, and Medical Equipment sectors, providing industry-leading versatility, durability, and precision-engineered solutions for diverse applications.

Torsion Helical Spring

A coiled spring that stores energy through twisting. It exerts torque when rotated. Features: Helical coil design, Angular deflection, Configurable leg shapes. Applications: Garage doors, Automotive hinges, Mechanical levers, Mousetraps.

Single Torsion Springs

Has one coil body with two legs extending from the ends. Features: Simple design, clockwise or counterclockwise wound. Applications: Used in clothespins, garage doors, and levers.

Double Torsion Springs

Two connected torsion springs coiled in opposite directions. Features: Greater force output, offers dual torque capabilities. Applications: Mechanical devices requiring balanced or increased torque, such as automotive components.

Barrel Torsion Springs

Tapered or conical-shaped torsion spring. Features: Reduced tendency to buckle under load, good space efficiency. Applications: Used in applications where space is limited, such as small machinery or instruments.

Flat Spiral Torsion Springs

Consists of a flat strip of material coiled in a spiral shape. Features: Large angular deflection, compact form. Applications: Watches, clock mechanisms, and retractable systems.

Constant Force Torsion Springs

Provides a nearly constant force throughout deflection. Features: Consistent torque output, minimal change in force. Applications: Used in applications requiring consistent tension, such as seat belts or retractable cables.

Our Custom Torsion Springs

Each type of bespoke torsion spring we offer is crafted with precision and tailored to meet the high standards of various industries. Our expertise in custom solutions ensures that no matter the application, our torsion springs deliver in terms of quality, performance, and reliability.

Torsion Helical Spring

A coiled spring that stores energy through twisting. It exerts torque when rotated.

Features: Helical coil design, Angular deflection, Configurable leg shapes.

Applications: Garage doors, Automotive hinges, Mechanical levers, Mousetraps.

Single Torsion Springs

Has one coil body with two legs extending from the ends.

Features: Simple design, clockwise or counterclockwise wound.

Applications: Used in clothespins, garage doors, and levers.

Double Torsion Springs

Two connected torsion springs coiled in opposite directions.

Features: Greater force output, offers dual torque capabilities.

Applications: Mechanical devices requiring balanced or increased torque, such as automotive components.

Barrel Torsion Springs

Tapered or conical-shaped torsion spring.

Features: Reduced tendency to buckle under load, good space efficiency.

Applications: Used in applications where space is limited, such as small machinery or instruments.

Flat Spiral Torsion Springs

Consists of a flat strip of material coiled in a spiral shape.

Features: Large angular deflection, compact form.

Applications: Watches, clock mechanisms, and retractable systems.

Constant Force Torsion Springs

Provides a nearly constant force throughout deflection.

Features: Consistent torque output, minimal change in force.

Applications: Used in applications requiring consistent tension, such as seat belts or retractable cables.

Custom Torsion Spring Applications

Explore the essential role of custom torsion springs across sectors. From household appliances to automotive, aerospace, and electronics, our springs ensure performance and reliability. Discover their impact in various industries, driving innovation and efficiency.

Precision in Printing: Custom Torsion Springs in 3D Printer Timing Belt Systems

Explore the essential role of our custom torsion springs in 3D printer timing belt systems, where they provide precise control and stability. These silver-colored springs ensure smooth and accurate movement of the printer’s parts, contributing to the high-quality printing results.

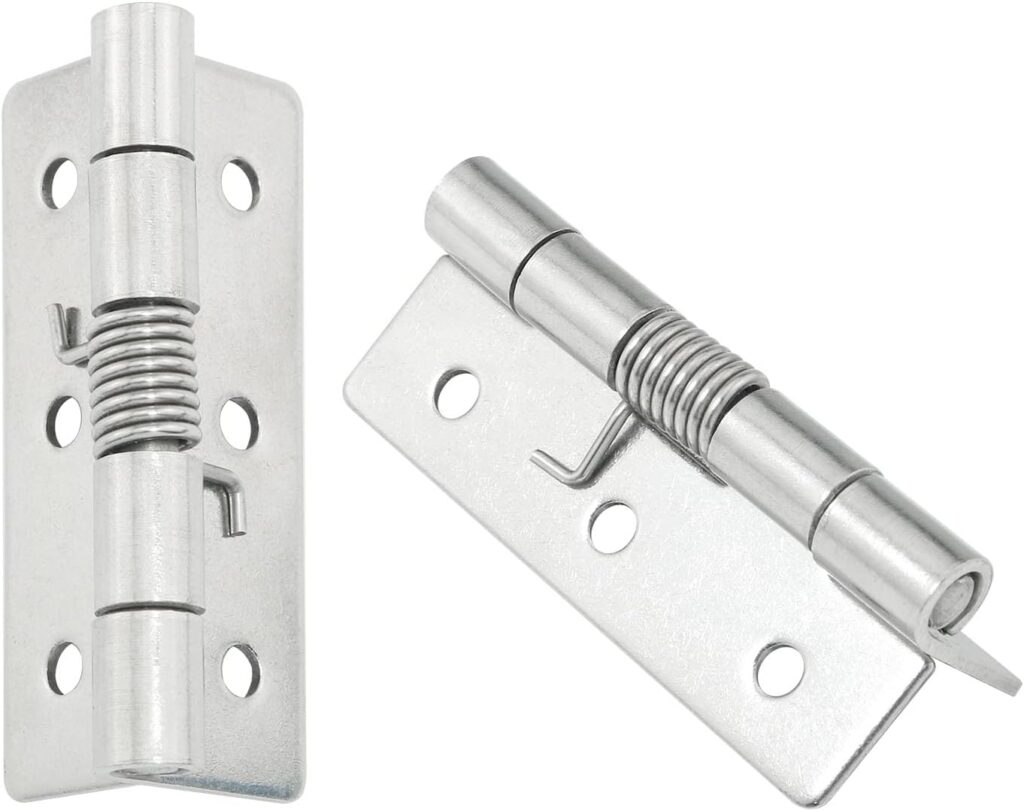

Custom Torsion Springs in Hinges: Enabling Smooth and Controlled Movements

Discover how torsion springs in hinges play a crucial role in ensuring doors and lids operate smoothly, providing the right amount of tension for controlled movements and reliable functionality.

csstom Spring Clips for LED Lights: Ensuring Secure and Sleek Installations

Dive into the functionality of custom spring clips in LED lighting, where they secure lights in place with ease and reliability. These clips ensure a stable and flush mount, enhancing the overall aesthetic and performance of LED installations.

Custom Torsion Spring Enhancements for Molded Trigger Mechanisms

Explore how custom torsion springs enhance molded triggers, offering precise control and reliable performance. Ideal for various applications, these springs ensure consistent functionality and durability.

Critical Force: The Role of Custom Torsion Springs in Garage Doors and Gates

Discover the critical role of torsion springs in garage doors and gates, where they provide the necessary force to lift heavy doors with ease. These springs balance the door’s weight, allowing for smooth opening and closing, enhancing both safety and convenience in home and commercial settings.

Your Expert in Custom Torsion Springs Manufacturing

Looking for custom torsion springs for your specific industrial needs ?

As a specialized custom torsion springs manufacturer China, Zigoal produce high-precision, durable torsion springs, tailored to your exact specifications. From material selection to final production, every step is meticulously managed to provide springs that perfectly align with your project’s needs.

All our custom torsion springs are fully customizable in size, material & surface finish,enabling your products to enhance performance and extend their lifespan.As a trusted torsion spring factory with over 30 years of experience, we provide comprehensive support for wholesalers,distributors, vendors, and bulk buyers.

Custom Torsion Springs: All You Need To Know

Torsion Spring Information

What are torsion springs?

Torsion springs are mechanical devices that store and release energy through a twisting or rotational motion. They exert a torque or rotary force when their arms are rotated around the central axis.

Torsion Spring Design and Customization

- Tailored Dimensions: Customizable to specific diameters, lengths, and angles to suit diverse applications.

- Material Selection: Variety of materials including stainless steel, high-carbon steel, and specialty alloys for different environmental and operational needs.

- End Type Customization: Options for different end types to fit into the unique mechanisms of different devices.

Torsion Spring Types

Our bespoke torsion springs are available in various types, each designed to meet specific application needs and operational requirements. This range includes:

- Single Coil Torsion Springs

- Double Coil Torsion Springs

- Conical Torsion Springs

- Heavy-Duty Torsion Springs

- Micro Torsion Springs

- Adjustable Torsion Springs

- Specialty Torsion Springs

We craft each torsion spring type with precision, ensuring they meet the high standards of various industries. Our expertise in custom torsion spring solutions guarantees quality, performance, and reliability, regardless of the application.

Custom Torsion Spring Material Selection

When selecting materials for custom made torsion springs, the key considerations involve the operational environment, required strength, durability, and specific application needs. At Zigoal, a custom torsion spring manufacturer China,we offer a range of materials, each with unique properties to suit different requirements:

- High-Carbon Steel

- Stainless Steel

- Music Wire

- Phosphor Bronze

- Nickel Alloys

- Beryllium Copper

- Titanium Alloys

Custom Torsion Springs Finishings&Coatings

Selecting the appropriate surface treatment for custom torsion springs is crucial for enhancing their performance, durability, and resistance to environmental factors. At Zigoal, we offer a variety of surface treatments, each serving specific purposes:

- Powder Coating

- Electroplating (Zinc, Nickel, Chrome)

- Black Oxide

- Phosphate Coating

- Passivation (for Stainless Steel)

- Anodizing (for Aluminum Alloys)

- Cadmium Plating

Each bespoke torsion springs surface treatment offers unique benefits and should be chosen based on the specific environmental conditions and operational demands the torsion spring will face.

Torsion Spring Applications

Torsion springs, with their ability to store rotational energy and release it when needed, find extensive use across various industries. Their versatility and efficiency make them integral components in numerous applications:

- Automotive Industry

- Electronics and Technology

- Home Appliances and Furniture

- Industrial Machinery

- Medical Devices

- Aerospace and Defense

- Consumer Goods

- Construction and Hardware

- And more

If you don’t see your industry listed, we specialize in creating custom torsion spring solutions tailored to your specific needs. Please contact us to explore how we can assist you.

How to Custom Torsion Springs?

Step-by-Step Guide to Customizing Your Torsion Springs with Zigoal

- Assess the Application: Determine the specific use-case for the torsion spring in your machinery or product.

- Operational Requirements: Consider the operational environment, load requirements, and lifecycle of the torsion spring.

- Material Options: Choose from stainless steel, high-carbon steel, or other specialty alloys based on environmental exposure and strength requirements.

- Material Properties: Understand how each material’s properties like corrosion resistance, tensile strength, and fatigue life affect the custom torsion spring’s performance.

- Spring Dimensions: Define the torsion spring coil diameter, wire size, and length of the spring.

- Leg Configuration: Specify the shape and orientation of the spring legs based on the connection requirements in your device.

- Calculate Torque: Determine the torque needed for your application to ensure the torsion spring can deliver the required rotational force.

- Endurance Limits: Ensure the torsion spring design meets the operational lifespan and endurance limits for its intended use.

- Treatment Options: Choose from powder coating, electroplating, black oxide, etc., depending on corrosion resistance needs and aesthetic preferences.

- Finish Impact: Consider how the surface treatment will impact the torsion spring’s function and lifespan.

- Sample Production: Request prototype torsion springs to test in your application.

- Performance Testing: Conduct tests to ensure the spring meets your operational requirements.

- Order Specifications: Provide the detailed specifications and quantities required.

- Lead Times and Delivery: Discuss production lead times and delivery schedules to align with your project timeline.

- Installation Guidance: Access to support for correct installation and use.

- Post-Sale Service: Availability of after-sales service for any adjustments or replacements needed.

Rapid Prototyping: Bringing Ideas to Life Quickly

Rapid prototyping is at the core of Zigoal’s manufacturing prowess. It’s about turning concepts into tangible products with speed and precision. Here’s a concise overview:

- Speedy Development: We cut lead times, delivering functional prototypes in days, not months.

- Cutting-Edge Tech: We employ 3D printing and CAD for intricate designs and material versatility.

- Cost-Effective: Our process minimizes waste and keeps projects on budget.

- Client Collaboration: We work closely with you, ensuring a tailored solution.

- Quality Assurance: Stringent testing guarantees top-notch quality.

- Market-Ready: Our prototypes are functional for market testing, easing the transition to mass production

Torsion Spring Manufacturing Process

When it comes to spring manufacturing, Zigoal leverages cutting-edge technology and expert craftsmanship to ensure precision and consistency in every step of the process.

Coiling

Heat Treating

Cleaning

Surface Treatment

Testing

Packaging

Zigoal can meet tight deadlines

Swift Custom Wire Forms Manufacturing in 5-20Days

Advanced Manufacturing Technology

Robust Supply Chain

Professional Workforce & Shift Flexibility

In-House Plating Facility

These Clients Trust in Us

At Zigoal, a leading custom wireform and spring supplier, we pride ourselves on building strong, lasting relationships with our diverse clients. Our journey as a mechanical spring expert has been marked by successful collaborations across industries, each with unique demands and high standards.

Frequently Asked Questions

Clearing the Confusion and Enhancing Customer Satisfaction Efficiency about Custom Torsion Spring Manufacturer China. Feel free to reach out to our professional team for expert guidance.

Absolutely, our expertise lies in crafting custom springs and wire forms tailored to your exact requirements. Contact us today to discuss your project.

We aim to support projects of all sizes and can often accommodate orders without a strict minimum quantity. Please contact us with your specific needs, and we’ll work together to find a solution.

You can contact our customer service for getting a quote, please provide:

- product dimensions, material type, surface treatment, quantity, and specific requirements

Detailed drawings or CAD files are highly beneficial for complex designs.

Surely! You can always request a sample before place the bulk order. Sample time usually will take 2-5 days, depends on the specifications you need. Request a sample now!

Production time depends on the complexity and quantity of your order. We typically complete orders within 5 to 20 days and will provide a specific estimated timeline with your order details.

- 30% Advance Fee

to pay 30% of the total cost upfront

- 70% Balance Fee

Complete your balance payment within a certain period before ship out and receive the products you ordered for.

To place an order, simply reach out to our sales team with your spring specifications and requirements. We’re here to guide you through the process, from initial design consultation to the delivery of your custom torsion springs.

We offer a wide range of materials for torsion spring manufacturing, including Carbon Steels, Stainless Steels, Copper Alloys, Nickel Alloys, Plastic Composites,Inconel and more.

Material choice depends on the application, including requirements for strength, flexibility, corrosion resistance, and temperature sensitivity.

Zigoal apply a range of finishes and coatings to your custom torsion springs, including zinc plating, nickel plating,chrome plating, powder coating, passivation, blacken and more to enhance corrosion resistance, improve conductivity, or meet other specific requirements.

We can fabricate torsion springs with a variety of leg configurations, including straight legs, bent legs, short hook ends, hinged ends, and looped ends, among others. Your application and installation requirements will guide the best choice for end type.

Quality is at the core of everything we do at Zigoal. From material selection to final inspection, our comprehensive quality control process includes dimensional verification, material testing, load testing and more to ensure each spring performs as expected in its application.

Yes, we provide custom packaging and logistics solutions for safe and efficient international delivery.

We ensure the confidentiality of your proprietary designs by signing Non-Disclosure Agreements, employing secure data systems, and rigorously training our staff in data protection.

Compression Spring (HS CODE)732020

Extension Spring (HS CODE)732020

Torsion Spring (HS CODE)732020

All kinds of wireforms (HS CODE) 732090

Flat Spring,Clock Spring,

Fourslide Spring & Stamping Parts

(HS CODE) 732010

Hi there, I am Annie Lin, the key account manager of Zigoal. Contact us to get a free quote and more expertise about custom metal springs and wire forms. Your project will meet a right solution with us.