Custom Clock Springs

Innovative design and manufacturing solutions for all your clock spring requirements

Why Choose Our Clock Spring?

High Energy Storage

Capable of storing significant amounts of rotational energy, which can be released in a controlled manner

Durability

Made from high-quality clock spring steel that can withstand repeated use without significant wear or loss of functionality

Corrosion-Resistant Coating

Advanced anti-corrosion finishes enhance our clcok springs’ durability in harsh environments

Consistent Force

Providing a consistent force over a wide range of movement, ensuring reliable performance in mechanisms

Explore Our Custom Clock Springs

Our custom clock springs are available in a variety of designs, including flat spiral springs, power springs, constant force springs, torsion springs, brush springs, flat coil springs, motor springs, and more. We tailor each spring to your specific needs, ensuring high-quality solutions for every application.

Custom Flat Spiral Springs

Looking for Custom flat spiral springs for compact, high-torque applications? Our precision-engineered springs deliver consistent force and durability, perfect for clocks, timers, and rewind mechanisms.

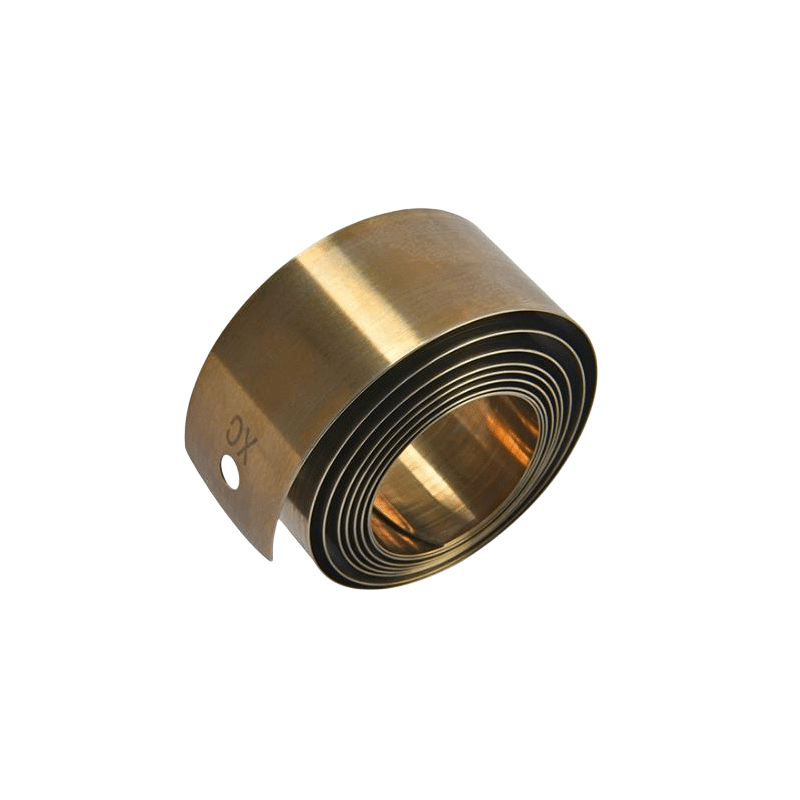

Custom Power Springs

Looking for custom power springs for energy storage with smooth, controlled release? Our power springs are tailored to your needs, delivering reliable performance for retractable devices like reels, seat belts, and tape measures.

Custom Constant Force Springs

Looking for custom constant force springs that provide uniform force over an extended range? Our springs are ideal for applications like counterbalances, door closers, and cable retractors, ensuring consistent performance with a steady load.

Custom Brush Springs

Looking for custom brush springs for optimal electrical contact and performance? Our precision-engineered springs ensure consistent pressure, perfect for electric motors, generators, and alternators.

Custom Flat Coil Springs

Looking for custom flat coil springs optimized for space efficiency and high performance? Our springs are perfect for applications like automotive clutches and switches, offering reliable performance with flat, coiled configurations.

Custom Motor Springs

Looking for custom motor springs for enhanced performance and durability in electric motors? Our motor springs are precision-engineered to meet the rigorous demands of motor and appliance manufacturers, ensuring reliable and optimal function.

Everything you need to know about Custom clock spring

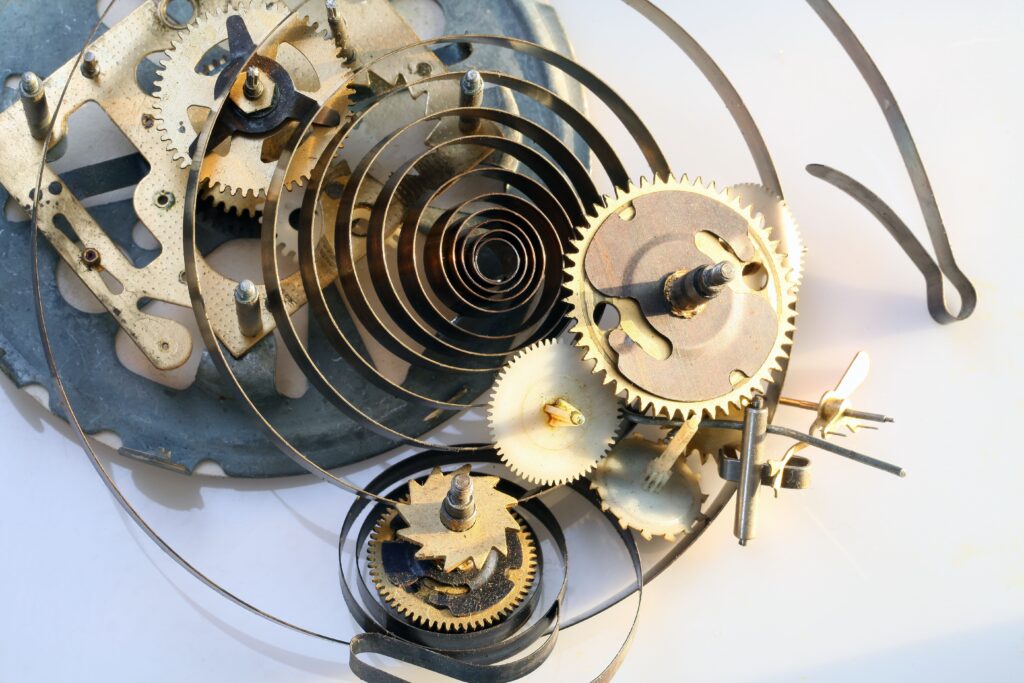

In-Depth Understanding of Clock Spring

What is Clock Spring?

A clock spring is a coiled strip of metal designed to provide rotational force. It returns to its original shape after being twisted, delivering consistent energy in various applications.

How Do Clock Springs work?

Clock springs store energy when wound and release it smoothly. The unique clock spring design operates on the principle that the force exerted is proportional to the amount of twist. This design ensures precise and efficient performance for applications needing controlled energy release.

Clock Spring Design Consideration

- Application Requirements: Our experts tailor custom springs to fit your specific needs.

- Material Selection: Choosing the right spring material affects strength, elasticity, and temperature resistance.

- Coil Diameter: This impacts rotational capacity and space compatibility.

- Thickness and Width: Affects torque capacity and energy storage; thicker springs store more energy.

- Length: Determines how much energy the spring can store and release.

- Space Constraints: Designed to fit in compact spaces without compromising performance.

- Durability and Lifespan: Designed for maximum reliability through optimized material and spring design.

Clock Spring Material

Zigoal offers an extensive selection of materials for our custom clock sring manufacturing process. Each material is available in various grades and specifications.Ensuring durability, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. Our materials include:

- Carbon Steel

- Music Wire

- Stainless Steel

- Phosphor Bronze

- Alloy Steel

- Beryllium Copper

- Inconel®

- Titanium

- Elgiloy®

- Hastelloy®

Can’t find the material in our listed for your custom manufacturing projects? please reach out to us to discuss how we can meet your needs.

Clock Spring Coatings & Finishes

- Powder Coating

- Electroplating

- Black Oxide

- Phosphate Coating

- Passivation (Stainless Steel)

- Anodizing (Aluminum Alloys)

- Cadmium Plating

At Zigoal, clock spring manufacturer offer a range of surface treatment options to ensure that your clock spring not only perform exceptionally but also meet your aesthetic and environmental requirements.

Clock Spring Applications

Clock springs are widely used in various applications requiring controlled rotational force. They are commonly found in automotive steering systems, retractable devices, clocks, and precision instruments, providing reliable energy storage and smooth motion control. Their versatile spring design makes them ideal for ensuring consistent and efficient performance in mechanical systems. examples of clock spring applications across different sectors:

Custom Clock Springs: Key to Precision Timekeeping

Custom clock springs (mainsprings) store mechanical energy, release it gradually, and drive the clock’s movement. They ensure accurate timekeeping by providing consistent force, essential for the reliability and longevity of traditional and modern clocks.

Ensuring Smooth Cable Management with Custom Constant Force Springs

Enhancing cable management, custom constant force springs provide consistent tension in cable reels, ensuring smooth extension and retraction. These springs improve usability and durability by maintaining even tension, optimizing the performance and lifespan of cable systems.

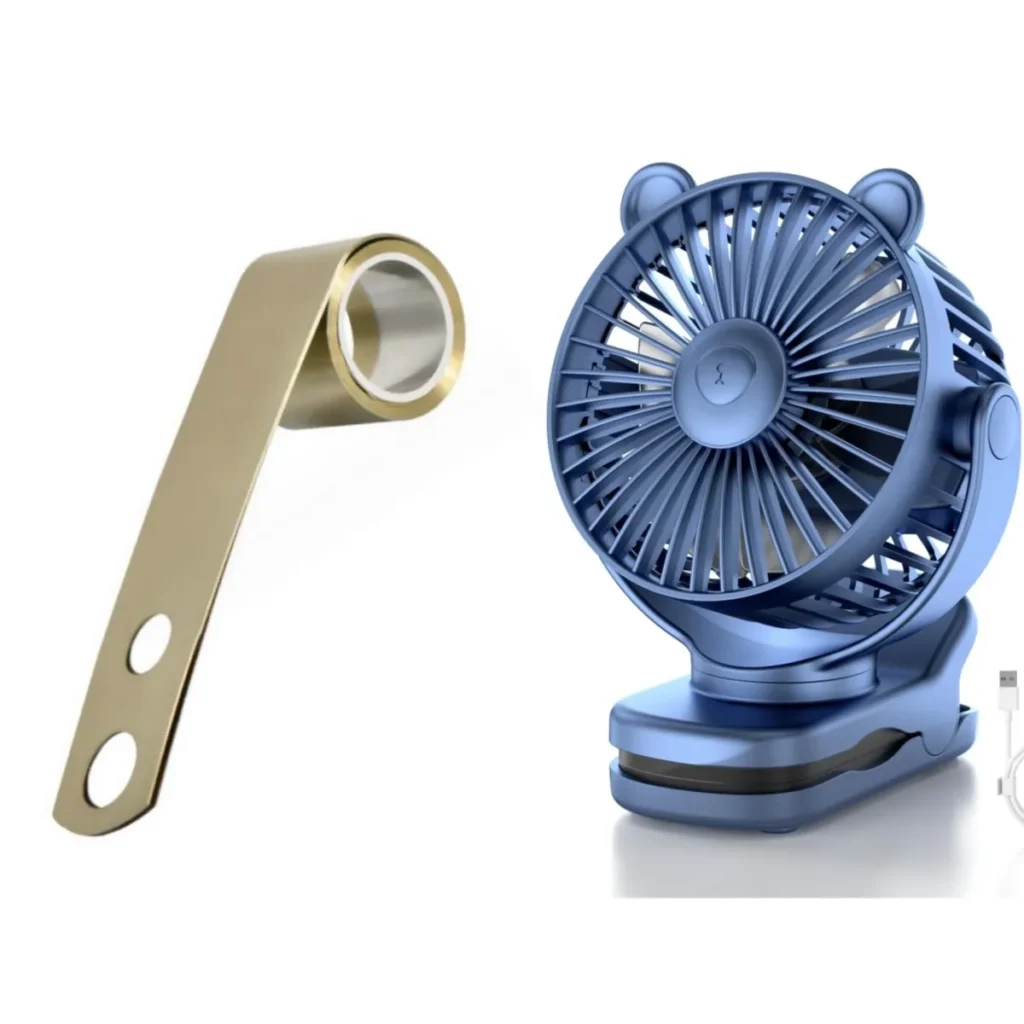

Custom Flat Spiral Springs: Enhancing Fan Performance and Reliability

Custom flat spiral springs optimize fan performance by providing essential tension for smooth operation and reliability. Their compact design enhances efficiency and ensures long-lasting functionality in fan systems.

Custom Power Springs: Streamlining Vending Machine Operations

Custom power springs are crucial in vending machines, storing energy to drive the dispensing mechanism. They ensure smooth, reliable product delivery, enhancing the efficiency and functionality of vending operations.

Custom Clockwork Springs: Ensuring Accuracy in Timepieces

Custom clockwork springs are vital for precision in mechanical watches, storing and releasing energy to power the movement. Their controlled energy release ensures accurate timekeeping and long-term reliability in timepieces.

Rapid Prototyping for Custom Clock Springs

Zigoal excels in rapid prototyping for custom clock springs, delivering precise, application-specific solutions.

Material Expertise: We utilize performance-optimized materials tailored for durability, ensuring clock springs perform seamlessly across diverse conditions.

Precision Engineering: Our advanced coiling technology replicates exact specifications, critical for the energy efficiency and reliability of your clock springs.

Customization and Testing: Prototypes undergo rigorous torsion testing, customized for integration with a focus on end configurations and load performance.

Speed and Iteration: Our fast iteration process allows for quick adjustments based on precise testing feedback, essential for performance optimization.

Why Zigoal is Trusted by 1000+ Clients?

Custom Spring Solutions

Zigoal specializes in tailored spring designs, ensuring precise customization to meet exact project specifications.

Precision Manufacturing

With a focus on quality and precision, Zigoal delivers high-performance, durable springs for diverse industrial applications.

Efficient Supply Chain

Zigoal's robust supply chain guarantees timely delivery and consistent product availability, crucial for maintaining project timelines.

Strict Quality Control

- Dimensional Inspection: Precise measurements ensure springs meet specified dimensions and tolerance levels.

- Material Testing: Verifies material properties like tensile strength, hardness, and composition to ensure compliance with required specifications.

- Load Testing: Confirms the correct force output by testing springs under specified loads and displacements.

- Fatigue Testing: Simulates long-term usage by testing springs through multiple cycles, predicting lifespan and performance.

- Environmental Testing: Springs for harsh conditions undergo additional tests, including corrosion resistance and temperature cycling, to ensure durability.

Certified Quality

Service Global. Precision Engineering. Quality Guaranteed. High Durability. No Failure. Optimal Performance.

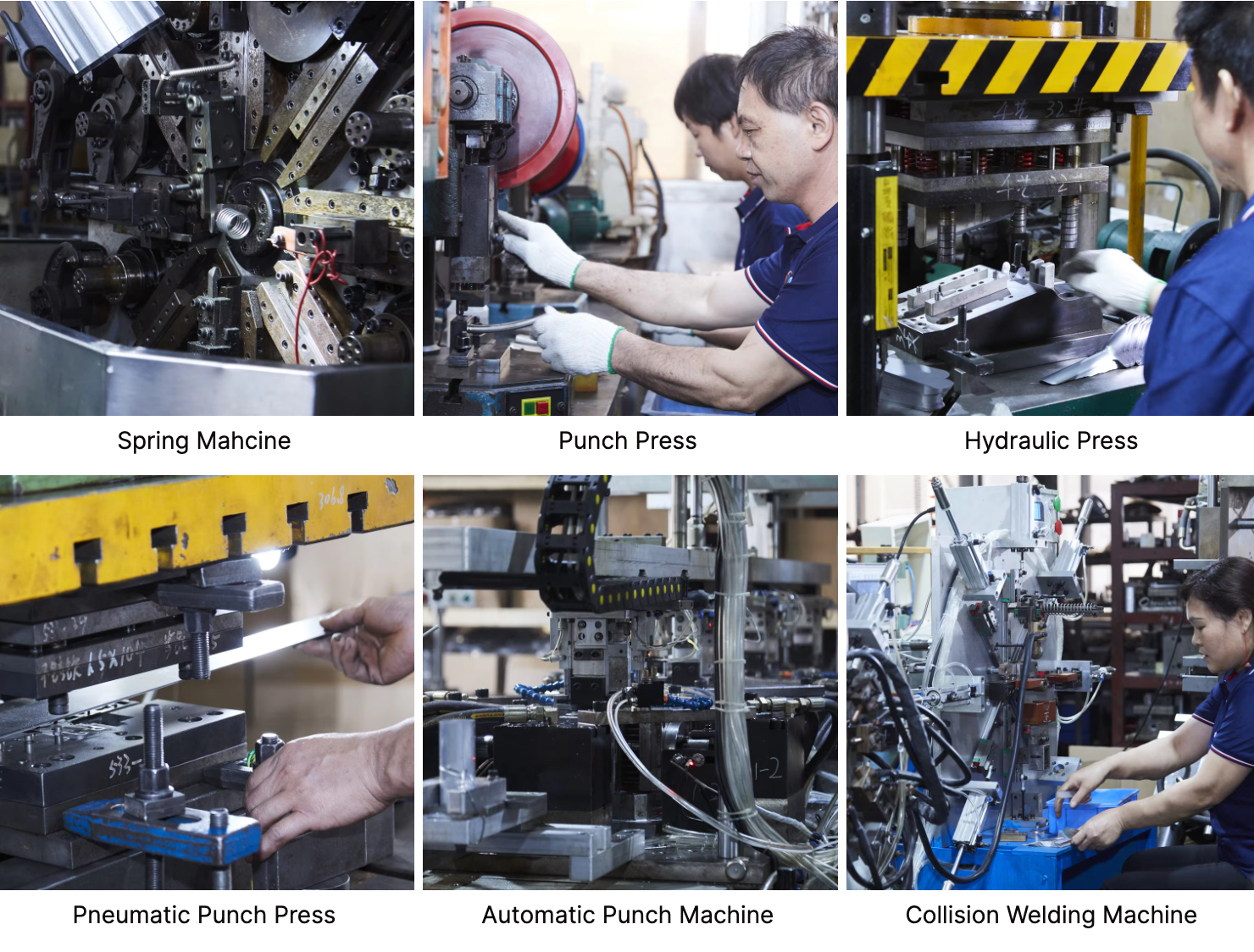

Clock Spring Manufacturing Process

Step-by-Step Overview of the Manufacturing Process

Spring Winding

End Shaping

Heat Treating

Cleaning

Surface Treatment

Testing

Extensive After-Sales Services at Zigoal

Each of these services is designed to provide comprehensive support, ensuring that our clients experience the full benefits of our custom spring solutions, long after the initial purchase

Technical Support

Providing ongoing expert assistance to ensure seamless integration and optimal performance of our custom springs in your applications

Product Warranty

Offering a comprehensive warranty, covering manufacturing defects and performance issues to ensure customer confidence and satisfaction

Regular Follow-Ups

Engaging in consistent communication with clients to gather feedback, which is crucial for continuous product and service improvement

Training

Organizing training sessions and workshops to educate clients about proper usage, maintenance, and handling of our springs

Part Upgrades

Keeping clients informed about upgrades or modifications that could enhance the performance of their current spring systems

Emergency Support

Offering emergency support to address urgent issues, ensuring rapid response to minimize downtime

Our Happy Clients Say

At Zigoal, we pride ourselves on building strong, lasting relationships with our diverse clientele. Our journey over the years has been marked by successful collaborations with a multitude of industries, each with unique demands and high standards.

Working with Zigoal has been a breeze. Their one-stop custom spring solutions have improved our machinery’s efficiency,their expertise and quality are unmatched. And Lily from their team is a pleasure to collaborate with.

In my role as Procurement Director at Tech Solutions, I’ve partnered with Zigoal for years, and their custom springs have always exceeded our expectations. Their expertise and quality are unmatched.

As a Robotics Strategic Project Manager at Global Robotics, I can confidently say that Zigoal’s compression springs have been an integral part of our robotic systems. Peter’s team provided tailored solutions that have been crucial to our success.

Frequently Asked Questions

Clearing the Confusion and Enhancing Customer Satisfaction Efficiency about Custom Clock Spring Manufacturer. Feel free to reach out to our professional team for expert guidance.

Production time depends on the complexity and quantity of your order. We typically complete orders within 5 to 20 days and will provide a specific estimated timeline with your order details.

Our approach to order sizes is flexible, and we’re here to meet your unique needs. Whether you require a small quantity or a larger order, we can accommodate you. Please feel free to get in touch with your specific requirements, and we’ll provide you with the best solution

You can contact our customer service for getting a quote, please provide:

- product dimensions, material type, surface treatment, quantity, and specific requirements

- If available, attach design drawings or samples of the springs or wire forms. This greatly helps in ensuring precision and meeting your exact requirements.

Surely! You can always request a sample before place the bulk order. Sample time usually will take 2-5 days, depends on the specifications you need. Request a sample now!

- 30% Advance Fee

to pay 30% of the total cost upfront

- 70% Balance Fee

Complete your balance payment within a certain period before ship out and receive the products you ordered for.

Sure,we offer design and engineering support to optimize the performance and cost-efficiency of custom clock springs. Leveraging our expertise can be valuable, especially for complex projects.

We offer a wide range of materials for custom clock spring manufacturing, including Carbon Steels, Stainless Steels, Copper Alloys, Phosphor Bronze, Nickel Alloys,Inconel and more to meet diverse environmental and application needs.

Custom clock springs can be finished with options like plating, powder coating, passivation, shot peening, stress relief, and electropolishing to enhance performance and appearance.

Clock spring lifespan varies based on material, design, and environment, but with proper maintenance, many springs last for years or even decades.

Regular inspection, appropriate lubrication, using the spring within designed load limits, and protecting it from harsh environments can extend its life.

Yes, we provide custom packaging and logistics solutions for safe and efficient international delivery.

We ensure the confidentiality of your proprietary designs by signing Non-Disclosure Agreements, employing secure data systems, and rigorously training our staff in data protection.

Compression Spring (HS CODE)732020

Extension Spring (HS CODE)732020

Torsion Spring (HS CODE)732020

All kinds of wireforms (HS CODE) 732090

Flat Spring,Clock Spring,

Fourslide Spring & Stamping Parts

(HS CODE) 732010

Hi there, I am Annie Lin, the key account manager of Zigoal. Contact us to get a free quote and more expertise about custom metal springs and wire forms. Your project will meet a right solution with us.