Compression springs, the helical open-coil springs that oppose compressive loading, are indispensable in a plethora of applications, ranging from the automotive to the electronic industries. As one of the most efficient energy storage devices, they not only absorb shock and maintain a force between two surfaces but also accommodate a wide variety of industrial needs with their flexibility and strength. This comprehensive guide delves into the various compression spring types, including conical compression springs,hourglass springs, barrel compression springs,variable rate springs and concave springs, among others, exploring their unique characteristics and applications.

Regular Compression Springs

Regular compression springs, known for their cylindrical shape and even dimensions, are a cornerstone in various applications due to their versatility and reliability. They are crafted through meticulous processes including coiling, stress relieving, and finishing, ensuring their durability and optimal performance. The materials used for these springs, such as stainless steel, hard-drawn steel, steel music wire, and spring steel, are selected for their strength and resilience, catering to the demanding requirements of different environments.

- Dimensions and Availability:

- Diameters: Range from 0.036 inch to 9.250 inch

- Free Lengths: Span from 0.130 inch to 9.880 inch

- Wire Diameters: Vary from 0.004 inch to 0.938 inch

- Customization: Offers extensive capabilities and engineering support from design through production

The applications of regular compression springs are vast and diverse, embedding them deeply in the fabric of everyday life and specialized machinery. From automotive engines and major appliances to sensitive instrumentation devices and electronics, these springs play a pivotal role. Their function is straightforward yet critical: upon application of a compression load, they compress and grow shorter, absorbing potential force. This energy absorption mechanism is vital for the smooth operation and longevity of the devices they are part of. When the load is reduced or eliminated, these springs return to their original lengths and forms, ready to perform again. This cycle of compression and relaxation, facilitated by their design, makes them indispensable in ensuring the functionality and reliability of countless devices.

Regular Compression Springs stand out for their commonality and effectiveness across various sectors:

- Automotive: Engine components, suspensions

- Industrial: Stamping presses, machinery

- Consumer Goods: Lawn mowers, major appliances

- Medical Devices: Instruments, equipment

- Electronics: Cell phones, sensitive instrumentation

Their ubiquity and the straightforward nature of their design, featuring straight coils with the same diameter, underscore their importance in both everyday items and complex machinery.

Conical Compression Springs

Conical compression springs, often referred to as tapered or cone springs, are distinguished by their unique shape where the outer diameters either increase or decrease, forming a cone-like structure. This design offers several advantages:

- Reduced Solid Height: The conical shape allows these springs to nest within themselves when compressed, significantly reducing the solid height compared to regular springs. This feature is particularly beneficial in applications where space is limited.

- Stability and Flexibility: Due to their tapered structure, conical springs provide enhanced stability and can accommodate higher loads within confined spaces, surpassing the capabilities of traditional straight springs. The flexibility in design also allows for tailored force and deflection characteristics, making them suitable for a wide range of applications.

- Progressive Rate: The varying diameter across the length of a conical spring results in a progressive compression rate. This means the spring can offer different amounts of force at different levels of compression, providing a more controlled response to applied loads.

Conical compression springs are available in various types, each designed to meet specific requirements:

- Simple Conical Springs: Standard tapered springs offering versatility.

- Mini Block Springs: Designed for minimal solid height.

- Cylindrical Center Springs: Feature a cylindrical portion for increased stability.

- Double Conical: Two tapered sections for a more complex force profile.

- Beehive Springs: Characterized by a varying coil diameter, resembling a beehive shape, for improved fatigue life.

- Waist Springs: Feature a narrowed center to provide specific load characteristics.

Despite their numerous advantages, it’s important to note that highly tapered conical springs may be prone to buckling under certain conditions. Additionally, these springs may have a more limited linear deflection range compared to other types of compression springs, requiring careful consideration during the design phase to ensure they meet the application’s needs. The manufacturing process, particularly variations in the angle of taper, can also influence the spring rate, highlighting the importance of precision in their production.

Barrel Compression Springs

Barrel Compression Springs stand out due to their unique design and functionality, catering to a wide range of industrial applications where space optimization and stability are key. The distinctive feature of these springs is their barrel shape, characterized by a larger diameter in the middle and smaller diameters at both ends. This design not only enhances the aesthetic appeal but also serves functional purposes, making them an ideal choice for applications requiring compact and efficient spring solutions.

Key Characteristics of Barrel Compression Springs:

- Shape and Design: The convex shape, with a larger center diameter, allows these springs to offer unique advantages over traditional compression springs.

- Customization: Primarily custom-made, these springs can be tailored to meet specific requirements, including wire diameters ranging from 0.006 inches to 0.100 inch, and various finishes such as zinc, gold zinc, and nickel plating.

- Functionality: Capable of producing linear or nonlinear force, they are adept at preventing buckling in longer springs by evenly distributing pressure, thus enhancing stability.

Applications Across Industries:

- Automotive: Utilized in components where space is a premium and stability under compression is crucial.

- Furniture: Ideal for mechanisms requiring compact springs that offer both aesthetics and functionality.

- Medical Devices: Their stability and customizability make them suitable for precise medical equipment.

Hourglass Compression Springs

Hourglass compression springs, characterized by their unique barbell shape, feature larger diameters on the end coils and smaller diameters on the middle coils. This distinctive design plays a crucial role in their functionality and application:

- Design and Functionality:

- Shape: The concave design, resembling an hourglass or barbell, optimizes space utilization and ensures stability.

- Pitch: Offers a constant or uniform pitch throughout its length, contributing to an increasing force rate as opposed to a constant force rate seen in regular springs.

- Stability and Buckling Resistance: Provides enhanced lateral stability and a reduced tendency to buckle under load compared to traditional compression springs.

Advantages of Hourglass Compression Springs:

- Resistance to Surging: Their unique shape provides increased resistance to surging during decompression, making them suitable for applications requiring high stability.

- Vibration Control: The uniform pitch contributes to reduced resonance and vibration, with a natural period of vibration increasing as each coil bottoms out. This feature is particularly beneficial in applications where minimizing vibration is crucial.

- Durability Considerations: While designing the springs to allow adjacent coils to rub against each other during deflection can increase resistance to resonance phenomena, it may also lead to shortened spring life due to wear.

Applications and Manufacturing Insights:

- Versatility in Use: These springs are calculated as two conical springs in series, designed to oppose compression along the axis of wind. Their hourglass shape is achieved by reducing the diameter of the coil at both ends, which not only aids in maintaining stability over a specific point but also enhances visual appeal in external or visible parts of devices.

- Manufacturability and Pricing: The production and cost factors for hourglass compression springs vary based on wire diameter, spring diameter, and overall shapes. Their longer free length that maintains stability, even when the free length is more than three times the mean diameter of the spring, adds to their versatility and application in a wide range of industries.

By incorporating these features and benefits, hourglass compression springs stand out as a critical component in various applications where stability, resistance to vibration, and efficient space utilization are paramount. Their unique design not only contributes to their functional advantages but also to their aesthetic appeal, making them a preferred choice for both internal mechanisms and external parts of devices where visual enhancement is desired.

Concave Springs

Unfortunately, it seems there was an oversight, and no specific key points or details were provided for the section on “Concave Springs.” Without this essential information, generating targeted and factual content for this section is not feasible. To maintain the integrity and continuity of the article, and to ensure it remains informative and valuable to readers, it’s crucial to have detailed insights into the characteristics, applications, and any unique attributes of concave springs.

In the context of compression spring types, concave springs, also possibly referred to in some contexts, might share similarities with other specialized spring forms in terms of their design purpose, application areas, or mechanical properties. They could potentially offer unique advantages in specific engineering or mechanical contexts, similar to how barrel, conical, and hourglass springs serve distinct roles based on their shapes and material properties.

To align with the article’s intent and maintain the quality and informative nature of the content, it would be beneficial to gather accurate and detailed information about concave springs. This could include their design specifications, typical uses in industry, any unique advantages they offer over other spring types, and considerations for their selection and application. Once this information is available, it will be possible to create a section that seamlessly integrates with the rest of the article, providing readers with comprehensive insights into compression spring types, including concave springs, and aiding in the selection of the optimal spring for their needs.

Variable Rate Springs

Variable Rate Springs are an innovative solution in the realm of compression springs, designed to offer varying spring rates along the length of the spring. This unique feature allows them to adapt to a wide range of applications, providing both flexibility and efficiency in performance. The varying spring rate is achieved through careful design and manufacturing processes, which adjust the coil spacing or wire diameter along the spring’s length. Here’s a closer look at how Variable Rate Springs function and their advantages:

- Design Mechanism:

- Coil Spacing: By altering the spacing between the coils, the spring can offer different levels of resistance at various points along its length. Closer coil spacing results in a stiffer spring section, while wider spacing offers more flexibility.

- Wire Diameter: Adjusting the wire diameter within the same spring can also change the spring rate. Thicker wire sections provide greater resistance, and thinner sections offer less resistance.

- Advantages:

- Adaptability: The ability to provide variable resistance makes these springs highly adaptable to changing loads, enhancing the performance of the application they are used in.

- Space Efficiency: They can perform the function of multiple springs by providing different rates of compression in a single component, saving valuable space in compact applications.

- Improved Performance: Variable Rate Springs are designed to improve the performance of applications by offering precise control over movement, reducing wear and tear on parts, and enhancing overall stability.

Variable Rate Springs find their application in a variety of industries, including automotive, where they are used in suspension systems to offer a smoother ride by adapting to different road conditions. They are also utilized in machinery and equipment that require precise movement control, where the variable resistance can reduce the risk of damage to sensitive components.

In summary, Variable Rate Springs represent a versatile and efficient solution in the field of compression springs. Their design allows for a customized response to compression forces, making them suitable for a wide array of applications where adaptability and performance are critical.

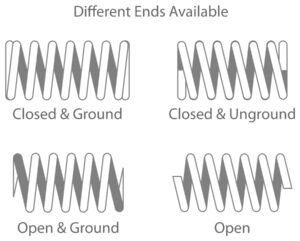

End Types in Compression Springs

Compression springs are designed with various end configurations to meet specific application requirements. The choice of end type can significantly impact a spring’s functionality, stability, and compatibility with mechanical assemblies. Below is a comparison of the most common end types found in compression springs:

- Closed and Squared Ends

- Most common type

- Allows the spring to stand vertically on a flat surface

- Provides good stability and grip, especially when not placed in a rod or shaft

- Closed and Ground Ends

- Second most common type

- Ensures the spring stands straight and vertically without a shaft or rod

- Offers better seating and reduces buckling, suitable for upright positions needing to withstand compression

- More expensive due to additional manual labor for grinding

- Open Ends

- Least common, requiring a shaft or rod for stability

- Produced when lower solid height and more active coils are required

- Useful in applications where the spring is placed in a rod or shaft

- Double Closed Ends

- Have two closed coils at the ends, providing stability for springs with high slenderness ratios

- More economical than closed and ground ends

- Offers more stability but may not be necessary if the spring is placed in a rod or shaft

The selection of end types is crucial for ensuring the optimal performance of compression springs in various applications. Here are key considerations when choosing the right end type:

- Stability Requirements: Closed and squared or closed and ground ends provide better stability for springs that need to stand vertically on a flat surface.

- Economic Considerations: Double closed ends are more economical than closed and ground ends but offer similar stability benefits.

- Application Specific Needs: Open ends are selected when a lower solid height and more active coils are required, often in cases where the spring is placed in a rod or shaft.

- Manufacturing and Cost: Closed and ground ends are more expensive due to the additional manual labor involved in grinding the ends. This process helps springs sit more flatly, reducing buckling and making the free length and spring rate more precise.

Understanding these end configurations and their implications is essential for designers and engineers when specifying compression springs for their projects. The choice of end type not only affects the spring’s functionality but also its manufacturing cost and application suitability.

Conclusion

Throughout this guide, we have explored the diverse world of compression springs, from their fundamental types such as regular, conical, barrel, hourglass, to the more specialized variable rate springs. Each category has been delineated based on its design, functionality, and suitability for various applications, highlighting the importance of selecting the appropriate spring type for specific requirements. The guide also underscored the significance of understanding end types in compression springs and furnished a structured approach to choosing the right compression spring, emphasizing the vital role of the spring finder tool in this process.

FAQs

What Are the Various Forms of Compression Springs?

Compression springs come in several shapes and designs, with the most common being conventional, conical spring, hourglass spring, barrel spring (concave spring), and reduced end designs. These variations cater to different application needs and functionalities.

How Can You Measure a Compression Spring Accurately?

To accurately measure a compression spring, follow these steps:

- Use calipers to measure the wire diameter of the spring, aiming for precision to three decimal places.

- Determine the outside diameter of the spring’s coils.

- Measure the spring’s length in its uncompressed (free) state.

- Count the total number of coils.

- Observe and note the direction in which the coils are wound.

What Should Be Considered When Selecting Compression Springs?

When choosing the right compression spring, it’s crucial to:

- Calculate the required spring rate, which is the force per unit of deflection. This calculation is based on the load the spring needs to support and the desired amount of deflection or travel.

- The spring rate is a key factor that affects how the spring will perform under different loads.