Diving into “Clock Spring Design: Key Parameters for Optimal Performance,” we explore the fusion of precision and innovation essential for crafting exceptional clock springs. This article will guide you through crucial design aspects—coil count, material choice, and dimensions—to surpass project expectations with durable, efficient springs. Gain the insights needed for success in the realm of mechanical engineering, ensuring your clock spring designs excel in functionality and performance.

Clock Spring Mechanism

The clock spring mechanism refers to a coiled ribbon of wire or metal strip designed to retract and store energy, then release it to provide a consistent force. Commonly found in automotive steering wheels, it maintains an electrical connection between the vehicle’s steering wheel and its electrical systems, such as airbag, horn, and control buttons, while allowing the wheel to turn. Beyond automotive uses, clock spring mechanisms are also utilized in wind-up toys, retractable key chains, and various mechanical devices where compact energy storage and controlled energy release are needed for operation. This mechanism is crucial for ensuring smooth, reliable operation in applications requiring rotational movement or the maintenance of an electrical connection through a rotating interface.

Clock Spring Design

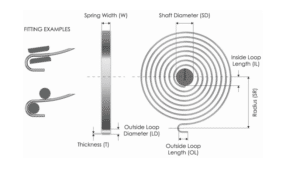

When designing a clock spring to meet specific torque requirements, the number of coils, thickness, width, and length of the spring are crucial factors that must be meticulously calculated and optimized. Each of these elements plays a vital role in determining the spring’s performance, durability, and suitability for its intended application. Here’s a deeper look into how these factors contribute to the overall design:

Number of Coils

- The number of coils in a clock spring directly influences its ability to store energy. More coils typically allow for more stored energy, which can result in a higher torque output over a longer duration. However, adding coils increases the physical size of the spring, which may not be feasible in space-constrained applications. The design must balance the desired torque with the available space, ensuring the spring can perform its function without occupying excessive room.

Thickness of the Clock Spring

- The thickness of the spring material affects its strength and how much force it can exert. Thicker springs are generally stronger and can handle higher loads, but they also require more force to wind or unwind. This factor must be carefully considered to ensure that the spring can achieve the necessary force without requiring more energy than what is available or practical in the system.

Width of the Clock Spring

- The width of the spring contributes to its strength and the total amount of energy it can store. Wider springs can distribute stress more evenly across their surface, potentially increasing their lifespan under repeated use. However, as with thickness and number of coils, increasing the width may not always be possible due to design constraints, making it essential to find an optimal balance that meets the torque requirements while fitting within the designated space.

Length of the Clock Spring

- The length of the spring, or how long it extends when fully unwound, determines the duration of action the spring can provide before needing to be rewound. A longer spring can offer a more prolonged period of force application, beneficial in applications requiring sustained energy release. The design must ensure that the spring length is compatible with the mechanism’s operational range, providing the needed force without exceeding the limits of the device’s structural components.

Clock spring materials and their properties

Clock springs are typically made of high-quality steel that exhibits excellent mechanical properties. The choice of material depends on the specific application and the desired characteristics of the spring. Clock spring steel is known for its high tensile strength, corrosion resistance, and fatigue resistance. Other materials, such as titanium alloys or nickel-based alloys, may be used for specialized applications that require unique properties. Clock spring specialists have a deep understanding of these materials and can guide you in selecting the most suitable option for your needs.

Understanding the function of clock springs

To fully appreciate the expertise of clock spring specialists, it is essential to understand the function of clock springs. Clock springs store energy when they are wound up, and this energy is gradually released to power a mechanism. The controlled release of energy ensures a consistent and reliable operation of the device. Clock spring specialists possess a comprehensive understanding of the mechanics behind this process and can optimize the design and performance of clock springs for various applications.

Different types of clock springs

Clock springs come in various forms to suit different applications. Some common types include Constant Force Springs, Power Springs, Spiral Torsion Springs, flat spiral springs, and coil springs. Constant Force Springs provide a constant force output over a wide range of deflection, making them ideal for applications that require consistent tension. Power Springs, on the other hand, are designed to store a large amount of energy in a compact space. Spiral Torsion Springs offer torsional energy storage and are commonly used in applications that require rotational force. Flat spiral springs and coil springs are versatile options that can be customized to meet specific requirements.

Common problems with clock springs

Clock springs, like any mechanical component, are susceptible to various issues that can affect their functionality. One common problem is fatigue failure, which occurs when the spring is subjected to repeated stress over time. This can lead to a loss of tension and a decrease in performance. Another issue is improper installation or winding, which can cause the spring to become misaligned or damaged. Clock spring specialists are well-versed in diagnosing and resolving these problems, ensuring that your device operates smoothly and reliably.

How to custom the right clock spring for your needs

Customized the right clock spring for your needs requires careful consideration of several factors. These include the desired force output, the available space, the required tension, and the specific application. Clock spring specialists can assist you in custom manufacturing the most suitable spring by considering these factors and leveraging their expertise in clock spring design.

Unlock the full potential of your mechanical devices with the expertise of clock spring experts. Contact us today to discuss your specific requirements and discover how our customized solutions can enhance the performance and reliability of your devices.

In mastering clock spring design, understanding key parameters is crucial for achieving optimal performance. We encourage you to leverage this knowledge to innovate and enhance your projects. For clock spring expert advice and further refinement in your clock spring design efforts, consider consulting with professionals. Contact Zigoal now to engineer excellence and ensure your designs not only meet but exceed expectations.