Custom Compression Springs Manufacturer

Delivering high-quality, reliable compression springs tailored to meet your exact specifications.

Custom Any Compression Springs for Your Project

Zigoal offers full capabilities in custom compression springs tailored to your project needs. We can manufacture according to your specific designs, dimensions, material types, surface finishes, and more too meet your specific needs.

Our Custom Compression springs Capability:

- .007 to .394Inches(10mm) In Wire Diameter

- RoundWire, Rectangular Wire, Square Wire & Special-Section Wire

- Custom Springs Manufactured to Meet Your Specific Needs

- Rapid prototyping and full-scale production

Contact Us Today to Discuss Your Custom Extension Spring Needs!

Why choose our Compression Springs?

High Fatigue Resistance

Offer lasting performance, resisting fatigue under continuous stress

Precision Tolerance

Crafted with tight tolerances for accurate, consistent performance in precision applications

Corrosion-Resistant Coating

Advanced anti-corrosion finishes enhance our compression springs’ durability in harsh environments

High-strength Materials

Ensuring longevity and resilience in demanding conditions

Explore Our Custom Compression Spring Types for Industry

Zigoal is a leading manufacturer of custom compression springs, offering a wide range of solutions.Below are just a small selection of the wire forms we have produced, including: conical springs, helical springs,garter springs, battery springs,magazine springs,stainless steel springs,copper compression springs and more. With a commitment to quality and performance, we provide versatile, durable, and customized wire forming tailored for diverse applications, ensuring reliability and excellence in every project.

conical springs

Part Names: Coil springs, compression springs, helical coil springs

Industry: Automotive, aerospace, manufacturing, and consumer electronics

Application: Absorbs shock, stores energy, or provides resistance under compression or tension, commonly used in suspension systems, machinery, and electronic devices

Material: Made from high-carbon steel, stainless steel, or alloy steel for strength and elasticity

Special Features:

Versatile Load Capacity: Customizable thickness and diameter for various load-bearing needs

Durability: Resilient to repeated stress with options for protective coatings against corrosion

High Elasticity: Provides reliable flexibility and resistance over a long service life

Helical Springs

Part Names: Coil springs, compression springs, helical coil springs

Industry: Automotive, aerospace, manufacturing, and consumer electronics

Application: Absorbs shock, stores energy, or provides resistance under compression or tension, commonly used in suspension systems, machinery, and electronic devices

Material: Made from high-carbon steel, stainless steel, or alloy steel for strength and elasticity

Special Features:

Versatile Load Capacity: Customizable thickness and diameter for various load-bearing needs

Durability: Resilient to repeated stress with options for protective coatings against corrosion

High Elasticity: Provides reliable flexibility and resistance over a long service life

Tapered Spings

Part Names: Conical springs, tapered coil springs, variable-diameter springs

Industry: Automotive, aerospace, electronics, and industrial machinery

Application: Designed to compress with a reduced solid height, ideal for applications needing space-saving load management, such as in suspensions, vibration dampening, and electrical contacts

Material: Typically crafted from stainless steel, high-carbon steel, or alloy steel for durability and strength

Special Features:

Compact Compression: Allows for a minimized height when fully compressed

Variable Load Response: Provides gradual resistance under compression

Enhanced Durability: Can be treated with corrosion-resistant coatings for longevity in demanding environments

garter springs

Part Names: Garter springs, circular springs, coil garter springs

Industry: Automotive, aerospace, medical devices, and industrial equipment

Application: Used to apply radial force or maintain tension in applications like shaft seals, O-rings, and belt-driven systems, ensuring a secure fit around circular components

Material: Commonly made from stainless steel or carbon steel for resilience and corrosion resistance

Special Features:

Elastic Tension: Continuous circular form provides uniform radial pressure

Versatile Sizing: Available in various diameters to fit different applications

Durability: Resistant to wear, with options for additional coatings for harsh environments

Battery Springs

Part Names: Battery contact springs, compression battery springs, battery terminal springs

Industry: Electronics, consumer devices, automotive, and medical equipment

Application: Provides reliable electrical contact and maintains pressure between batteries and terminals in devices like flashlights, remote controls, and portable electronics

Material: Typically made from nickel-plated steel or stainless steel for conductivity and corrosion resistance

Special Features:

Consistent Contact: Ensures stable electrical connection even under movement or vibration

Compact Design: Fits within small compartments, ideal for portable devices

Corrosion Resistant: Plated to resist rust, extending service life in various environments

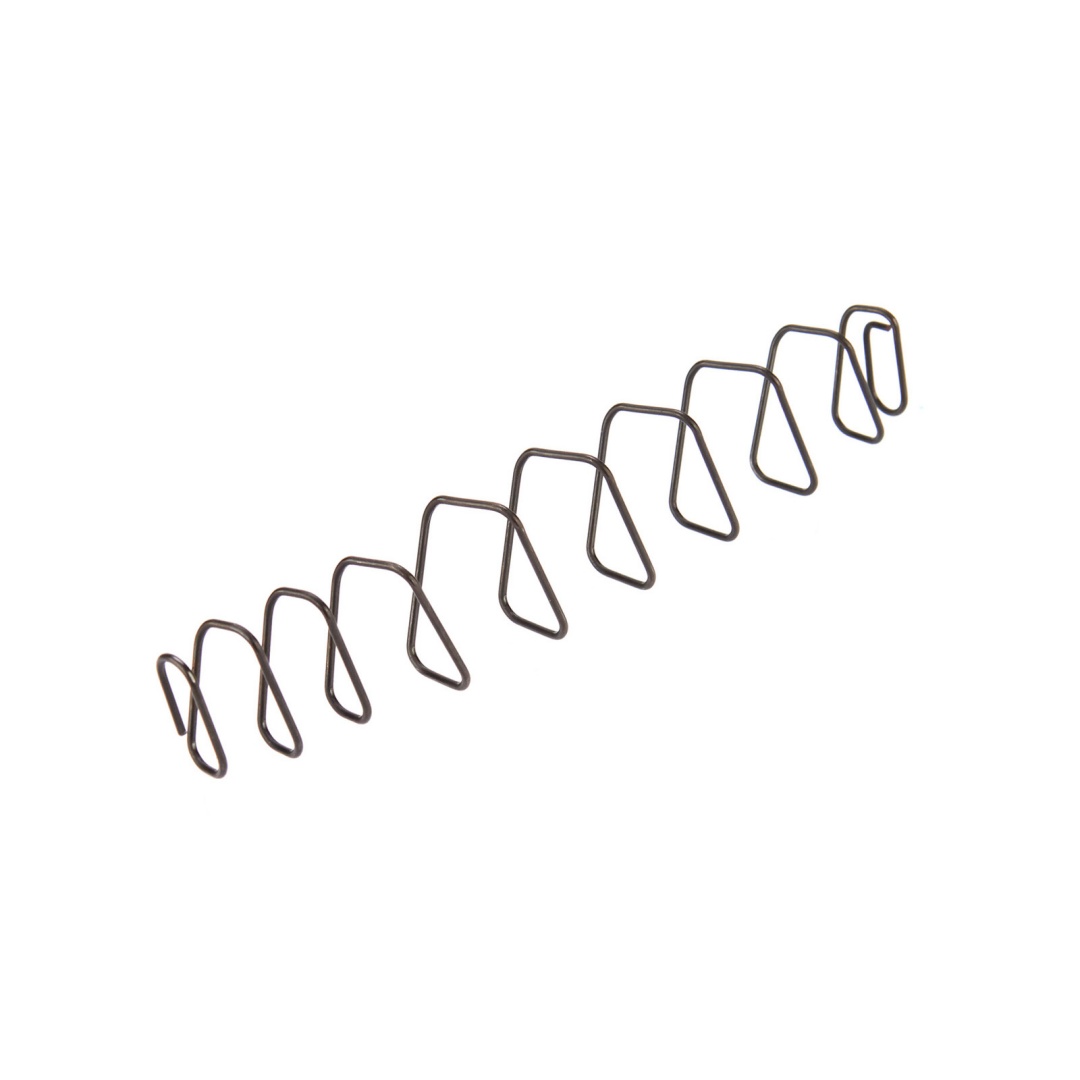

Magazine springs

Part Names: Magazine springs, compression springs for magazines, firearm magazine springs

Industry: Firearms, defense, and sporting goods

Application: Provides consistent pressure to feed ammunition rounds smoothly from a magazine into a firearm's chamber, ensuring reliable cycling and preventing jams

Material: Typically made from high-carbon steel or stainless steel for strength, fatigue resistance, and durability under repeated compression

Special Features:

Consistent Tension: Maintains uniform pressure to feed rounds reliably

High Durability: Engineered to withstand high-stress cycles without losing tension

Corrosion Resistant: Often treated with coatings to resist moisture and extend lifespan in diverse conditions

Hourglass Spring

Part Names: Hourglass spring, barrel spring, concave spring

Industry: Automotive, aerospace, medical devices, and industrial machinery

Application: Provides stable compression with lateral stability, commonly used in applications requiring centered force, such as precision instruments, suspension systems, and shock absorbers

Material: Typically constructed from stainless steel, high-carbon steel, or alloy steel for strength and resilience

Special Features:

Lateral Stability: Narrow center diameter reduces buckling under compression

Space Efficiency: Unique shape allows for compact height when compressed

Durability: Resistant to high-stress cycles, with options for protective coatings for corrosion resistance

Chamber Return Spring

Part Names: Chamber return spring, recoil spring, return coil spring

Industry: Firearms, automotive, industrial machinery

Application: Provides force to return a chamber, slide, or component to its original position after displacement, essential in firearm recoil systems and mechanical assemblies requiring reset functionality

Material: Typically made from stainless steel, high-carbon steel, or alloy steel for durability and consistent performance

Special Features:

High Elasticity: Maintains reliable force and flexibility for repeated compression cycles

Shock Absorption: Absorbs recoil or impact forces, enhancing stability

Corrosion Resistant: Often treated for resilience in demanding environments

Barrel Spring

Part Names: Barrel spring, concave spring, tapered coil spring

Industry: Automotive, aerospace, electronics, and precision instruments

Application: Provides controlled compression and stability, ideal for applications that require centered force distribution, such as suspensions, actuators, and shock-absorbing components

Material: Commonly made from stainless steel, high-carbon steel, or alloy steel for durability and resistance to fatigue

Special Features:

Centered Force: Tapered shape provides even pressure and reduces lateral movement

Compact Design: Collapses into a shorter height, making it suitable for tight spaces

Enhanced Durability: Withstands high-stress cycles and environmental exposure, with optional protective coatings

long Compression springs

Part Names: Long compression springs, extended coil springs, heavy-duty compression springs

Industry: Automotive, aerospace, industrial machinery, and agricultural equipment

Application: Used to absorb shock, provide force, or resist compressive loads over a greater distance, ideal for suspension systems, industrial presses, and heavy-duty machinery

Material: Typically made from stainless steel, high-carbon steel, or alloy steel to ensure strength, resilience, and durability under repeated use

Special Features:

Extended Travel Distance: Designed to handle greater deflection while maintaining stability

High Load Capacity: Withstands heavy compressive forces without deformation

Corrosion Resistant: Available with protective coatings for increased longevity in harsh environments

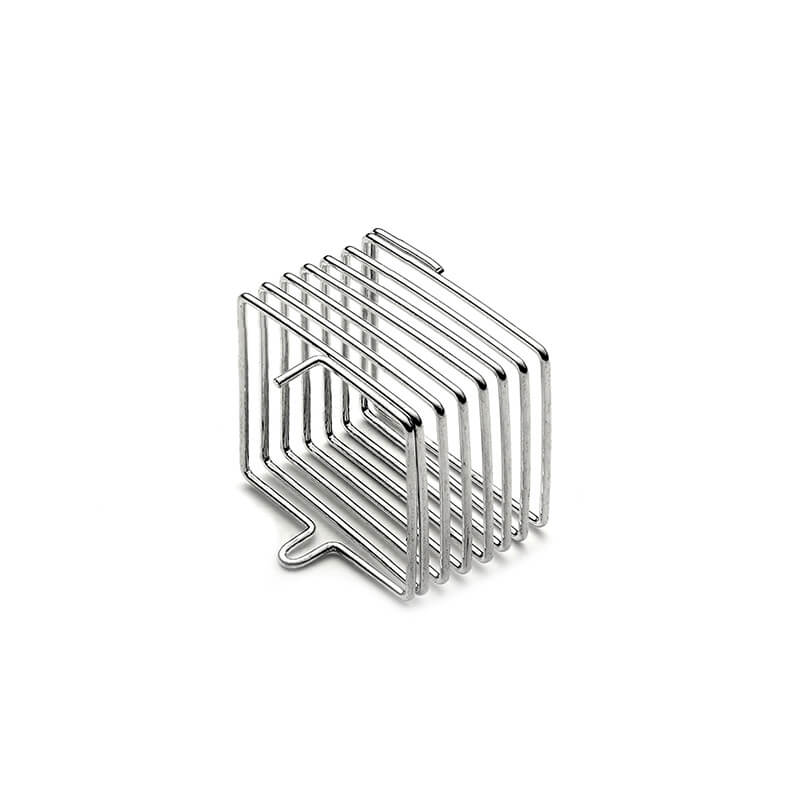

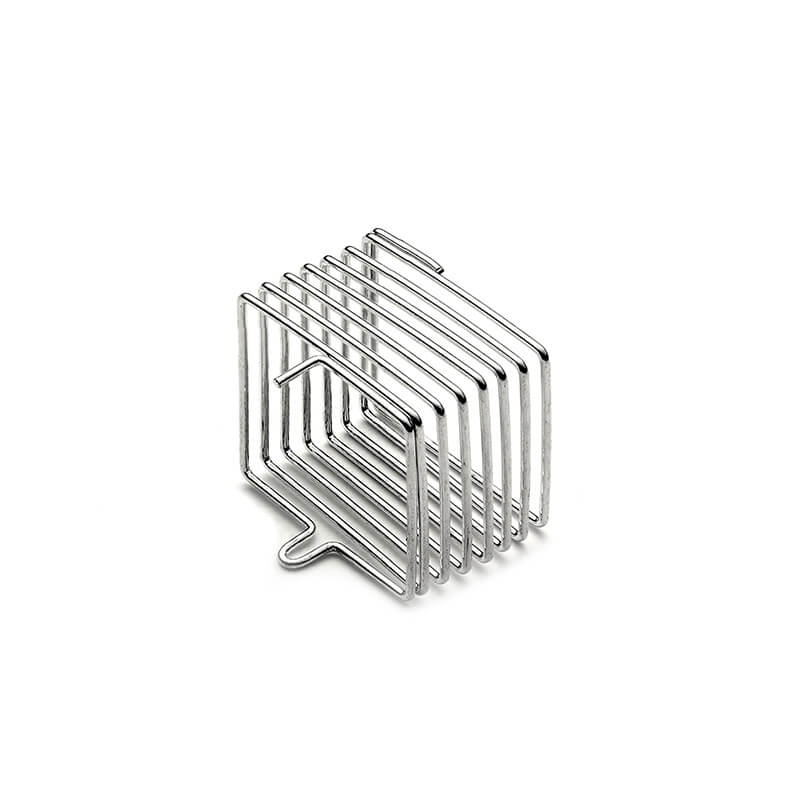

Square Compression Spring

Part Names: Square compression spring, square wire spring, square coil spring

Industry: Automotive, aerospace, industrial machinery, and electronics

Application: Provides compressive force with greater load capacity and compact spacing, often used in high-stress applications like valve systems, shock absorbers, and heavy-duty machinery

Material: Made from square-sectioned stainless steel, high-carbon steel, or alloy steel for increased durability and strength

Special Features:

Increased Load Capacity: Square wire shape allows for a higher load-bearing capacity compared to round-wire springs

Efficient Space Usage: Fits more coils in a smaller space, ideal for compact applications

Enhanced Stability: Resists twisting and lateral movement under load, maintaining alignment

Stove Handles

Part Names: Stove handles, oven handles, range handles, cooktop handles

Industry: Appliance manufacturing, home goods, and commercial kitchen equipment

Application: Provides a safe, ergonomic grip for opening and closing oven doors or adjusting stove settings, commonly found on residential and commercial stoves, ovens, and ranges

Material: Typically made from stainless steel, heat-resistant plastic, or coated metal to withstand high temperatures and frequent use

Special Features:

Heat Resistance: Designed to remain cool to the touch, preventing burns

Ergonomic Design: Shaped for a comfortable, secure grip

Durability: Built to endure high temperatures, repeated use, and cleaning without wear or deformation

short compression springs

Part Names: Short compression springs, compact coil springs, mini compression springs

Industry: Electronics, automotive, medical devices, and precision instruments

Application: Provides force in small spaces, ideal for devices with limited room like battery compartments, switches, and compact mechanical assemblies

Material: Made from stainless steel, high-carbon steel, or alloy steel for strength and durability

Special Features:

Space-Efficient Design: Fits into compact spaces without sacrificing performance

Reliable Force Output: Delivers consistent compression in tight areas

Durability: Resistant to deformation under repeated use in confined environments

music wire compression spring

Part Names: Music wire spring, music wire compression spring, high-tensile compression spring

Industry: Automotive, aerospace, electronics, and industrial machinery

Application: Provides high-tensile force and durability, commonly used in precision devices, automotive applications, and instruments where strong, reliable compression is required

Material: Made from high-carbon steel music wire, known for its strength, elasticity, and excellent fatigue resistance

Special Features:

High Tensile Strength: Handles significant loads and stress without losing shape

Excellent Fatigue Resistance: Ideal for applications with frequent compression cycles

Cost-Effective: Provides durability and performance at a relatively low cost

copper compression spring

Part Names: Copper spring, copper compression spring, conductive compression spring

Industry: Electronics, telecommunications, automotive, and medical devices

Application: Provides compression with excellent conductivity, commonly used in electrical contacts, grounding systems, and applications requiring corrosion resistance

Material: Made from copper or copper alloys (such as beryllium copper) for conductivity and durability

Special Features:

High Conductivity: Ideal for electrical applications, ensuring efficient current flow

Corrosion Resistance: Resilient in harsh environments, reducing oxidation

Non-Magnetic: Suitable for sensitive electronic components where magnetism must be minimized

small compression springs

Part Names: Mini compression springs, micro compression springs, tiny coil springs

Industry: Electronics, medical devices, automotive, and precision instruments

Application: Provides force and shock absorption in compact spaces, ideal for small devices like switches, sensors, and battery contacts

Material: Typically made from stainless steel, music wire, or phosphor bronze for strength in delicate applications

Special Features:

Compact Design: Fits into confined spaces without compromising functionality

Precise Force: Delivers consistent compression in miniaturized assemblies

Durable Construction: Resilient under repeated compression cycles, even in small dimensions

heavy compression springs

Part Names: Heavy-duty compression springs, high-load compression springs, industrial compression springs

Industry: Automotive, construction, industrial machinery, and agriculture

Application: Absorbs shock and supports high loads in applications requiring substantial force, such as suspensions, heavy machinery, and industrial presses

Material: Typically made from high-carbon steel, alloy steel, or stainless steel for maximum strength and load-bearing capacity

Special Features:

High Load Capacity: Built to withstand intense compressive forces without deformation

Durability: Resilient under repeated heavy-duty use and extreme conditions

Corrosion Resistant Options: Available with protective coatings for outdoor or harsh environments

stainless steel compression springs

Part Names: Stainless steel springs, stainless compression springs, corrosion-resistant compression springs

Industry: Automotive, marine, medical devices, electronics, and industrial machinery

Application: Provides compressive force in environments where corrosion resistance is essential, ideal for outdoor equipment, medical instruments, and electronics exposed to moisture

Material: Made from stainless steel grades such as 302, 304, or 316 for enhanced durability and corrosion resistance

Special Features:

Corrosion Resistance: Withstands exposure to moisture, chemicals, and extreme temperatures

Long-Lasting Durability: Maintains integrity and resilience in high-stress applications

Non-Magnetic Options: Some grades offer low or non-magnetic properties, ideal for sensitive applications

Custom Compression Spring Applications

Cylindrical Springs Applications

Cylindrical springs are compression springs with a consistent diameter along their length.

Automotive Industry: Used in suspension systems, shock absorbers, and engines to absorb impact and maintain force.

Machinery: Common in moving parts for force application and pressure maintenance.

Electronics: These springs provide contact force in connectors and button batteries.

Aerospace: Used in landing gears to absorb significant impact and stress under high load conditions.

Conical Springs Applications

These springs have a tapered design with varying diameters, making them compact when compressed.

Space-constrained environments: Ideal for applications with limited space for compression.

Automotive Transmissions: Facilitate smooth gear transitions due to their compact size.

Valve Systems: Provide precise force in applications like fluid control valves, ensuring reliable operation in compact spaces.

Tapered Springs Applications

Tapered springs have a gradually decreasing diameter, offering both stability and lightweight properties.

Load Distribution: Useful where gradual load distribution is required to prevent mechanical failure.

Seals: Provide controlled force in dynamic sealing applications.

Vibration Control: Applied in vibration absorption for high-load areas with limited space.

Compression Coil Springs Applications

A common type of compression spring that resists axial compressive forces, storing energy in the process.

Pressure Control: Utilized in compressors and pumps for managing pressure flows.

Heavy Equipment: Found in machinery like cranes and bulldozers, where they bear significant loads and ensure stability.

Medical Devices: Used in devices like inhalers to deliver precise dosages by controlling the release of energy.

Helical Springs Applications

Helical compression springs feature a helical coil design, offering a variety of applications in force management.

Automotive Suspension: Essential in shock absorption and maintaining vehicle height in coil-over suspensions.

Door Mechanisms: Control the closing force in doors and lids, ensuring smooth, gradual movement.

Toys & Mechanical Tools: Applied in wind-up mechanisms, where stored energy is gradually released.

Precision Compression Springs Applications

Precision compression springs are custom-designed to meet exact specifications, ensuring precise force application and reliability in specialized industries.

Medical Implants: Used in critical devices like pacemakers, where reliability and precision are vital.

Aerospace & Defense: Applied in satellites and defense systems, where precision and performance in extreme conditions like vacuum and radiation are crucial.

Electronics: Found in circuit breakers and connectors, where specific force requirements ensure performance and durability.

Scientific Instruments: Critical for precise movement in high-end measuring instruments, allowing for accurate results.

Ready to Start Your Custom Compression Spring Project?

Contact us now to experience unparalleled custom compression spring solutions tailored for your needs.

Rapid Prototyping for Custom Compression Springs

Rapid prototyping is at the core of Zigoal’s manufacturing capabilities, focused on transforming concepts into precise, tangible products efficiently.

Speedy Development: Our compression springs are designed to meet application requirements swiftly, cutting lead times to deliver prototypes within days.

- Cutting-Edge Design: Utilizing advanced spring design techniques such as CAD and 3D printing, we ensure the versatility of tension spring designs to meet load requirements.

- Cost-Effective Production: The design process minimizes waste while adhering to load requirements, keeping projects within budget.

- Client Collaboration: We understand spring needs closely and collaborate to provide tailored spring solutions.

- Quality Assurance: With rigorous testing protocols for each tension spring, our process guarantees the highest quality.

- Market-Ready Prototypes: Our prototypes are designed for practical application and initial tension testing, easing the transition to mass production.

Why Zigoal is Trusted by 1000+ Clients?

One-stop Custom Solutions

The ability to customize springs to specific requirements is crucial. As an engineer, ensuring that the springs fit the exact specifications of the project is paramount.

Quality and Precision

Quality and precision in manufacturing are crucial for durable, high-performance springs.

Robust Supply Chain Management

Efficient supply chain management ensures timely delivery and consistent product availability, critical for project timelines.

Strict Quality Control

- Dimensional Inspection: Precise measurements ensure springs meet specified dimensions and tolerance levels.

- Material Testing: Verifies material properties like tensile strength, hardness, and composition to ensure compliance with required specifications.

- Load Testing: Confirms the correct force output by testing springs under specified loads and displacements.

- Fatigue Testing: Simulates long-term usage by testing springs through multiple cycles, predicting lifespan and performance.

- Environmental Testing: Springs for harsh conditions undergo additional tests, including corrosion resistance and temperature cycling, to ensure durability.

Certified Quality

Service Global. Precision Engineering. Quality Guaranteed. High Durability. No Failure. Optimal Performance.

Know About Custom Compression Spring

Compression Spring Design

Custom compression spring design includes factors like spring rate, coil diameter, wire type, and spring index to ensure optimal performance and suitability.

Spring Rate: Determines the force needed for compression. Higher rates suit heavy-duty applications, while lower rates fit low-force uses.

Coil Diameter: Affects strength and flexibility. Larger diameters offer more load capacity, while smaller ones enhance flexibility.

Wire Type: Material selection (e.g., stainless steel, chrome silicon) impacts performance. Chosen based on environmental conditions and strength needs.

Spring Index: The ratio of coil diameter to wire diameter affects manufacturability. An optimal range ensures smooth production.

Performance & Suitability: Balancing these factors ensures the spring meets application requirements—from automotive to precision electronics.

Compression Spring Types For Optimal Performance

Different Varieties of Compression Springs and Their Characteristics

Cylindrical Springs

These basic compression springs provide linear force when compressed and are used in applications requiring linear motion.

Conical Springs

Conical springs have a tapered shape that progressively increases force as they compress, making them ideal for applications requiring gradual force buildup.

Hourglass Springs

Hourglass-shaped springs distribute load evenly across their length, reducing stress concentrations. They are used in space-limited applications or where uniform force is critical.

Barrel Spring

Barrel springs have a larger center diameter that reduces toward the ends, offering stability and control in applications needing buckling resistance.

Variable pitch Compression Springs

Variable pitch compression springs have varying coil distances, providing non-linear force characteristics. They are used in applications requiring precise control of force or damping.

Nested Compression Springs

Nested compression springs consist of multiple springs nested inside each other, offering high load capacity and a longer deflection range, ideal for heavy-duty applications.

square springs

Square springs have square or rectangular cross-sections, offering more contact surface and increased force compared to round wire springs. They are ideal for applications requiring compact design and high energy storage.

Barrel Spring

Barrel springs have a larger center diameter that reduces toward the ends, offering stability and control in applications needing buckling resistance.

Custom Compression Spring Ends

Compression springs come with various types of ends to suit different applications. Some common types of compression spring ends include:

closed ends

Variable pitch compression springs have varying coil distances, providing non-linear force characteristics. They are used in applications requiring precise control of force or damping.

double closed ends

Nested compression springs consist of multiple springs nested inside each other, offering high load capacity and a longer deflection range, ideal for heavy-duty applications.

open ends

Square springs have square or rectangular cross-sections, offering more contact surface and increased force compared to round wire springs. They are ideal for applications requiring compact design and high energy storage.

grounded ends

Barrel springs have a larger center diameter that reduces toward the ends, offering stability and control in applications needing buckling resistance.

At Zigoal, we understand that the choice of material is critical in spring manufacturing. Different extension spring materials offer unique properties, making them suitable for specific applications. Our extension spring experts will assist you in selecting the ideal material for your custom made extension springs.

Carbon Steel: Commonly used due to its strength, affordability, and availability.

Stainless Steel: Provides corrosion resistance and durability in harsh environments.

Alloy Steel: Offers enhanced performance under high stress and temperature conditions.

Phosphor Bronze: Known for its electrical conductivity and corrosion resistance, ideal for electrical components.

Beryllium Copper: Highly conductive with good fatigue strength, often used in precision instruments.

Inconel: A high-performance alloy resistant to extreme temperatures and corrosion, suitable for aerospace and industrial applications.

Music Wire: High-carbon steel wire known for its excellent fatigue life and high tensile strength.

Custom Compression Spring Finishings

Zinc Plating: a popular finish that provides corrosion resistance and an attractive appearance.

Electropolishing: a process that enhances surface smoothness, reduces friction, and increases corrosion resistance.

Powder Coating: A durable, colored finish that adds an extra layer of protection against wear and tear.

Passivation: A chemical treatment that removes contaminants and improves the spring’s resistance to oxidation.

Phosphate Coating: Enhances lubrication properties and corrosion resistance, ideal for industrial applications.

Nickel Plating: Offers a shiny, decorative appearance while providing excellent resistance to corrosion.

Teflon Coating: Creates a low-friction surface, making it ideal for applications requiring smooth movement.

Black Oxide Finish: Improves aesthetics while providing a moderate level of corrosion resistance.

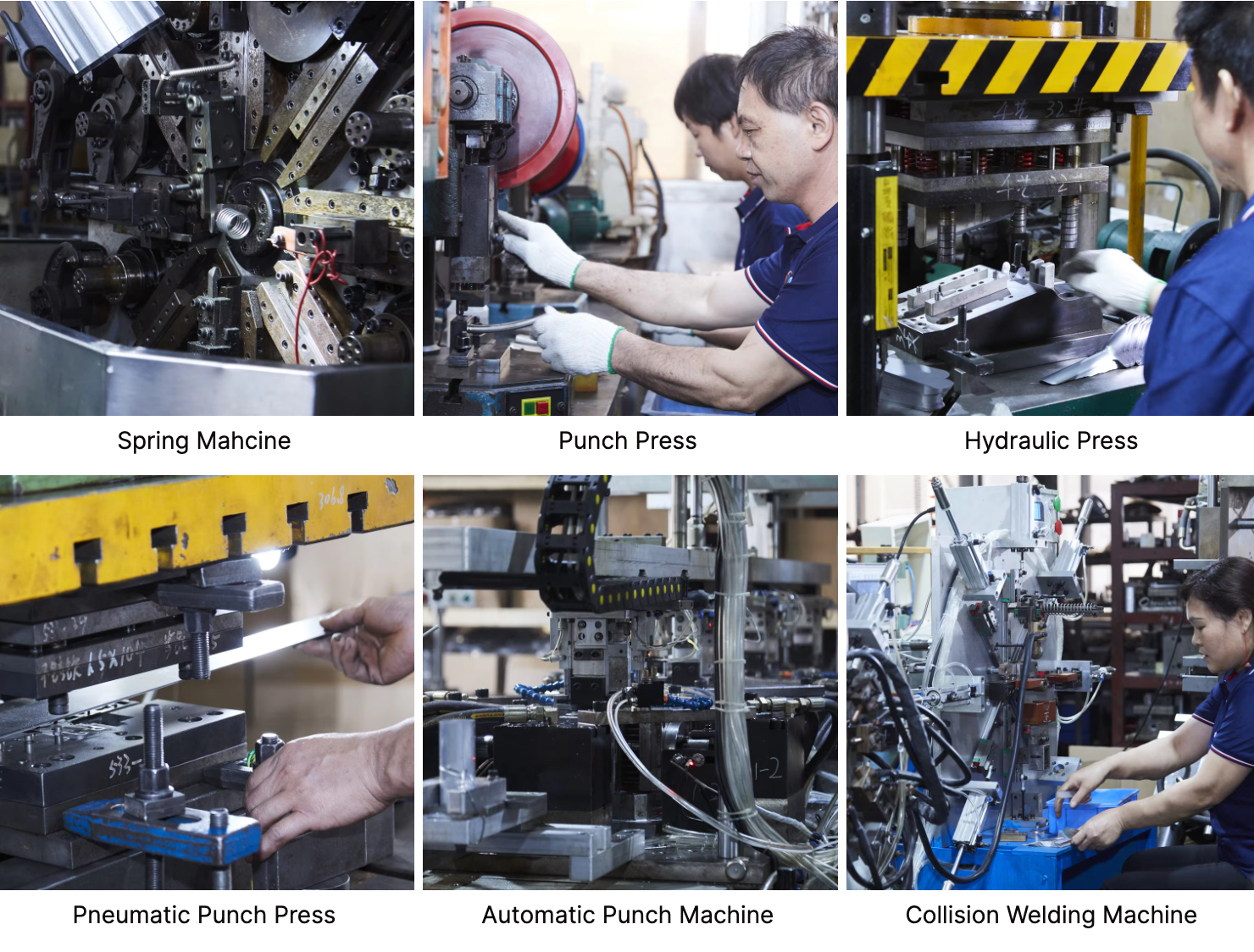

Compression Spring Manufacturing Process

When it comes to spring manufacturing, Zigoal leverages cutting-edge technology and expert craftsmanship to ensure precision and consistency in every step of the process.

Coiling

Heat Treating

Cleaning

Surface Treatment

Testing

Packaging

Zigoal can meet tight deadlines

Swift Custom Wire Forms Manufacturing in 5-20Days

Advanced Manufacturing Technology

Robust Supply Chain

Professional Workforce & Shift Flexibility

In-House Plating Facility

Extensive After-Sales Services at Zigoal

Each of these services is designed to provide comprehensive support, ensuring that our clients experience the full benefits of our custom spring solutions, long after the initial purchase

Technical Support

Providing ongoing expert assistance to ensure seamless integration and optimal performance of our custom springs in your applications

Product Warranty

Offering a comprehensive warranty, covering manufacturing defects and performance issues to ensure customer confidence and satisfaction

Regular Follow-Ups

Engaging in consistent communication with clients to gather feedback, which is crucial for continuous product and service improvement

Training

Organizing training sessions and workshops to educate clients about proper usage, maintenance, and handling of our springs

Part Upgrades

Keeping clients informed about upgrades or modifications that could enhance the performance of their current spring systems

Emergency Support

Offering emergency support to address urgent issues, ensuring rapid response to minimize downtime

Our Happy Clients Say

At Zigoal, we pride ourselves on building strong, lasting relationships with our diverse clientele. Our journey over the years has been marked by successful collaborations with a multitude of industries, each with unique demands and high standards.

Working with Zigoal has been a breeze. Their one-stop custom spring solutions have improved our machinery’s efficiency,their expertise and quality are unmatched. And Lily from their team is a pleasure to collaborate with.

In my role as Procurement Director at Tech Solutions, I’ve partnered with Zigoal for years, and their custom springs have always exceeded our expectations. Their expertise and quality are unmatched.

As a Robotics Strategic Project Manager at Global Robotics, I can confidently say that Zigoal’s compression springs have been an integral part of our robotic systems. Peter’s team provided tailored solutions that have been crucial to our success.

Frequently Asked Questions

Clearing the Confusion and Enhancing Customer Satisfaction Efficiency about Custom Compression Spring Manufacturer. Feel free to reach out to our professional team for expert guidance.

Absolutely, our expertise lies in crafting custom extension springs tailored to your exact requirements. Contact us today to discuss your project.

Our approach to order sizes is flexible, and we’re here to meet your unique needs. Whether you require a small quantity or a larger order, we can accommodate you. Please feel free to get in touch with your specific requirements, and we’ll provide you with the best solution

You can contact our customer service for getting a quote, please provide:

- product dimensions, material type, surface treatment, quantity, and specific requirements

- If available, attach design drawing or sample of the extension spring. This greatly helps in ensuring precision and meeting your exact requirements.

Surely! You can always request a sample before place the bulk order. Sample time usually will take 2-5 days, depends on the specifications you need. Request a sample now!

Lead times vary based on the complexity of the design, material availability, quantity. Typically complete orders within 5 to 20 days. We will provide an estimated delivery time with your quote, and we always aim to meet or exceed your timing requirements.

We offer various shipping options to meet your needs, including standard, expedited, and freight shipping. Shipping details and costs will be provided with your quote, ensuring you receive your order when and how you need it.

Our goal is to make receiving your order as easy and convenient as possible, wherever you are in the world.

Hi there, I am Annie Lin, the key account manager of Zigoal. Contact us to get a free quote and more expertise about custom metal springs and wire forms. Your project will meet a right solution with us.