Custom Metal Stampings

high-quality metal components for industrial and commercial needs with precision and reliability.

Custom Any Metal Stampings for Your Project

Zigoal offers full capabilities in custom metal stamping tailored to your project needs. We can manufacture according to your specific designs, dimensions, material types, surface finishes, and more. Our engineers can customize your orders through a variety of services and processes:

- We utilize precision CNC winding for accurate spring and wire form creation

- Zigoal employs advanced grinding techniques to achieve the perfect surface finish and tolerance

- Zigoal uses state-of-the-art techniques for coiling, bending, and shaping to meet any custom requiremen

- We offer shot peening to enhance fatigue strength

Contact Us Today to Discuss Your Custom Metal Stamping Needs!

Explore Our Bespoke Metal Stampings

Our custom metal stamping parts are available in various types including custom flat spring,custom fasteners clips,custom flat spring clip, custom fourslide spring,Custom button spring clip,custom tube spring clip, custom sheet metal stamped and more.

Custom Flat Springs

Are you looking for custom flat springs designed for precision and durability? Our custom flat springs are engineered to meet your specific requirements, providing reliable force and flexibility for a wide range of applications.

Custom Flat Spring Steel Strips

Are you looking for custom flat spring steel strips? Our custom flat spring steel strips are tailored to meet the highest standards, providing the perfect balance of strength and flexibility for your specific applications.

Custom Button Spring Clip

Are you in need of custom button spring clips for secure, easy-to-use fastening solutions? Our custom button spring clips are engineered for quick release and secure hold, making them perfect for a wide range of applications.

Custom Fourslide Spring

Are you searching for custom fourslide springs tailored to complex configurations? Our custom fourslide springs are produced with precision, offering versatile shapes and functions for industrial applications.

Custom Flat Spring Clip

Are you looking for custom flat spring clips for simple, effective fastening solutions? Our precision-engineered flat spring clips provide strong retention and are customizable to fit your unique application.

Custom Fasteners Clips

Are you in search of custom fasteners clips that offer secure holding and easy installation? Our custom-designed fasteners clips are made for maximum reliability and efficiency.

Why choose our Custom Metal Stampings?

High Fatigue Resistance

Offer lasting performance, resisting fatigue under continuous stress

Precision Tolerance

Crafted with tight tolerances for accurate, consistent performance in precision applications

Corrosion-Resistant Coating

Advanced anti-corrosion finishes enhance our springs’ durability in harsh environments

Customizability

Creating custom solutions, allowing for a wide designs, materials, and finishes to meet specific customer requirements.

Recent Custom Metal Stamping Parts

In the past decade, Zigoal has supplied custom metal stampings solutions to major players in industries such as Automotive, Electronics Manufacturing, and Medical Equipment, demonstrating our versatility and excellence in meeting diverse industry needs.

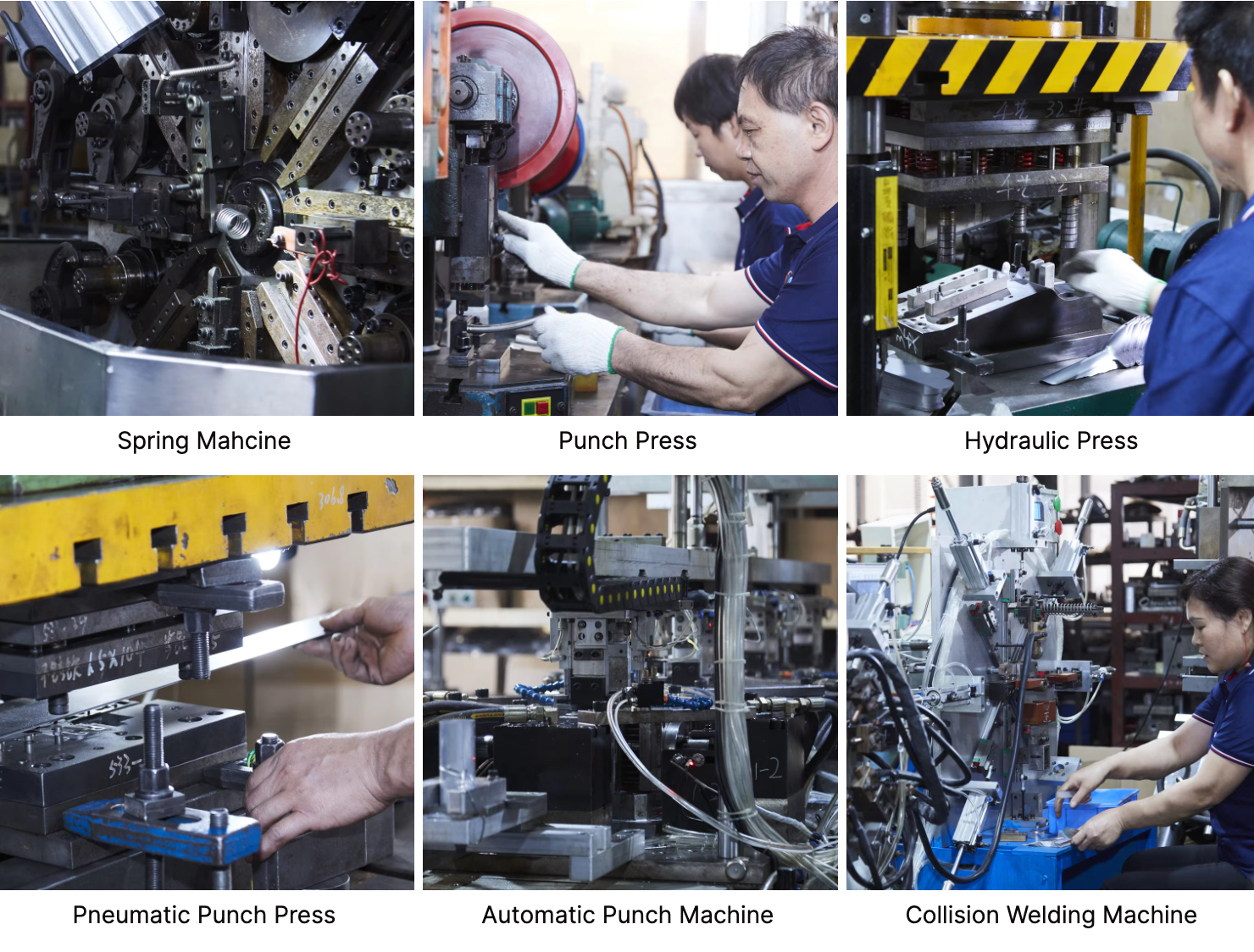

Techniques in Custom Metal Stampings

The manufacturing of custom metal stamping involves a variety of techniques to shape, form, and finish the springs to meet specific application requirements. Here are some common techniques used in the custom flat spring manufacturing process:

Cutting and Punching

- Laser Cutting: Offers precision and is ideal for complex shapes.

- Water Jet Cutting: Used for materials that are sensitive to high temperatures.

- Punching: A cost-effective method for simpler designs and larger production runs.

Heat Treatment

- Annealing: Softens the metal, making it easier to form.

- Tempering: Increases toughness of the spring.

- Quenching: Hardens the steel by cooling it rapidly.

Forming and Bending

- CNC Bending: For precise bending of metal strips into specific angles and shapes.

- Stamping: Utilizes dies and presses to form complex shapes quickly.

Assembly and Integration

- Welding:Joins metal parts permanently.

- Riveting: Joins parts together using a metal pin or rivet.

- Screw Fastening: For adjustable or disassemblable assemblies.

Material You Can Choose for Your Custom Metal Stampings

Zigoal offers an extensive selection of materials for our custom metal stamping manufacturing process. Each material is available in various grades and specifications.Ensuring durability, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. Our materials include:

- Carbon Steel

- Music Wire

- Stainless Steel

- Phosphor Bronze

- Alloy Steel

- Beryllium Copper

- Inconel®

- Titanium

- Elgiloy®

- Hastelloy®

Can’t find the material in our listed for your custom manufacturing projects? please reach out to us to discuss how we can meet your needs.

Available Surface Finishes for Custom Metal Stampings

Zigoal provides a diverse selection of custom surface finishes to enhance the protection, durability, and aesthetic appeal of your custom metal stamping. Each surface finish offers unique benefits tailored to specific applications and environmental conditions. Our surface treatment options include:

- Passivation

- Painting

- Titanium Nitride Coating

- Heat Treatment

- Anodizing

- Zinc Plating

- Chrome Plating

- Nickel Plating

- Powder Coating

- Black oxide

If you have specific requirements for surface finishes,please don’t hesitate to reach out to us!

Custom Metal Stampings Applications Across Industries

Metal stamping are integral components across a broad spectrum of industries, owing to their versatility, compactness, and efficiency in energy storage and release. Below, we explore their application across various sectors, including automotive, electronics, and aerospace, highlighting specific case studies to illustrate their importance.

Automotive Industry

In the automotive sector, flat springs are commonly used in suspension systems, such as leaf springs for trucks and heavy-duty vehicles. They absorb shock and maintain a vehicle’s connection with the road, enhancing ride quality.

Custom Flat Spring Steel Strips for the Electronics Industry

Elevate your electronics with our Custom Flat Spring Steel Strips, engineered specifically for the electronics industry. Our precision-crafted strips provide unmatched durability and conductivity, essential for high-performance electronic devices.

Aerospace Industry

The aerospace industry utilizes flat springs in various applications, including seat mechanisms, locking devices, and valve controls. Their high strength-to-weight ratio is particularly beneficial in this industry, where reducing weight while maintaining performance is crucial.

Custom Metal Stamping for the Medical Equipment Industry

Discover the precision and reliability of our custom metal stamping services tailored for the Medical Equipment Industry. Our state-of-the-art stamping processes ensure high-quality, durable components essential for medical devices.

Manufacturing and Industrial Equipment

In industrial settings, custom fasteners clips are used in machinery for holding, releasing, moving, or positioning parts. This includes applications in conveyor systems, safety guards, and tensioning devices.

Unlock Cost Savings and Quality

Don’t compromise on quality or budget. Contact us now to find out how our custom metal stampings can save you money while maintaining exceptional quality

Rapid Prototyping: Bringing Ideas to Life Quickly

Rapid prototyping is at the core of Zigoal’s manufacturing prowess. It’s about turning concepts into tangible products with speed and precision. Here’s a concise overview:

- Speedy Development: We cut lead times, delivering functional prototypes in days, not months.

- Cutting-Edge Tech: We employ 3D printing and CAD for intricate designs and material versatility.

- Cost-Effective: Our process minimizes waste and keeps projects on budget.

- Client Collaboration: We work closely with you, ensuring a tailored solution.

- Quality Assurance: Stringent testing guarantees top-notch quality.

- Market-Ready: Our prototypes are functional for market testing, easing the transition to mass production

Why Zigoal is Trusted by 1000+ Clients?

One-stop Custom Solutions

The ability to customize springs to specific requirements is crucial. As an engineer, ensuring that the springs fit the exact specifications of the project is paramount.

Quality and Precision

Quality and precision in manufacturing are crucial for durable, high-performance springs.

Robust Supply Chain Management

Efficient supply chain management ensures timely delivery and consistent product availability, critical for project timelines.

Strict Quality Control

- Dimensional Inspection: Precise measurements ensure springs meet specified dimensions and tolerance levels.

- Material Testing: Verifies material properties like tensile strength, hardness, and composition to ensure compliance with required specifications.

- Load Testing: Confirms the correct force output by testing springs under specified loads and displacements.

- Fatigue Testing: Simulates long-term usage by testing springs through multiple cycles, predicting lifespan and performance.

- Environmental Testing: Springs for harsh conditions undergo additional tests, including corrosion resistance and temperature cycling, to ensure durability.

Certified Quality

Service Global. Precision Engineering. Quality Guaranteed. High Durability. No Failure. Optimal Performance.

These Clients Trust in Us

At Zigoal, a leading custom wireform and spring supplier, we pride ourselves on building strong, lasting relationships with our diverse clients. Our journey as a mechanical spring expert has been marked by successful collaborations across industries, each with unique demands and high standards.

Our Happy Clients Say

At Zigoal, we pride ourselves on building strong, lasting relationships with our diverse clientele. Our journey over the years has been marked by successful collaborations with a multitude of industries, each with unique demands and high standards.

Working with Zigoal has been a breeze. Their one-stop custom spring solutions have improved our machinery’s efficiency,their expertise and quality are unmatched. And Lily from their team is a pleasure to collaborate with.

In my role as Procurement Director at XYZ Tech Solutions, I’ve partnered with Zigoal for years, and their custom springs have always exceeded our expectations. Their expertise and quality are unmatched.

As a Robotics Strategic Project Manager at Global Robotics, I can confidently say that Zigoal’s compression springs have been an integral part of our robotic systems. Peter’s team provided tailored solutions that have been crucial to our success.

Frequently Asked Questions

Clearing the Confusion and Enhancing Customer Satisfaction Efficiency about Custom Metal Stamping Manufacturer. Feel free to reach out to our professional team for expert guidance.

Absolutely, our expertise lies in crafting custom flat springs tailored to your exact requirements. Including variations in thickness, width, length, and forming of specific features for mounting or operational purposes. Contact us today to discuss your project.

Our approach to order sizes is flexible, and we’re here to meet your unique needs. Whether you require a small quantity or a larger order, we can accommodate you. Please feel free to get in touch with your specific requirements, and we’ll provide you with the best solution

You can contact our customer service for getting a quote, please provide:

- product dimensions, material type, surface treatment, quantity, and specific requirements

- If available, attach design drawings or samples of the flat springs. This greatly helps in ensuring precision and meeting your exact requirements.

Surely! You can always request a sample before place the bulk order. Sample time usually will take 5-7 days, depends on the specifications you need. Request a sample now!

Production time depends on the complexity and quantity of your order. We typically complete orders within 10 to 20 days and will provide a specific estimated timeline with your order details.

- 30% Advance Fee

to pay 30% of the total cost upfront

- 70% Balance Fee

Complete your balance payment within a certain period before ship out and receive the products you ordered for.

We offer a wide range of materials for flat spring manufacturing, including Carbon Steels, Stainless Steels, Copper Alloys, Nickel Alloys, Plastic Composites,Inconel and more.

Material choice depends on the application, including requirements for strength, flexibility, corrosion resistance, and temperature sensitivity.

Zigoal apply a range of finishes and coatings to your custom flat springs, including zinc plating, nickel plating,chrome plating, powder coating, passivation, blacken and more to enhance corrosion resistance, improve conductivity, or meet other specific requirements.

Custom flat springs are specialized mechanical devices designed to store and release energy. Unlike traditional coil springs, they are flat and often offer unique advantages such as space-saving design and precise force characteristics.

With over a decade in the industry, Zigoal adheres to rigorous quality control throughout our manufacturing process, including material inspection, dimensional checks, load testing, visual inspection and more to ensuring every spring meets and exceeds industry standards in consistency and performance.

Yes, at Zigoal, we offer door-to-door shipping services for all international orders. You can relax on your sofa while we handle the logistics, ensuring your order arrives directly to your doorstep without any hassle. Our goal is to make receiving your order as easy and convenient as possible, wherever you are in the world.

We ensure the confidentiality of your proprietary designs by signing Non-Disclosure Agreements, employing secure data systems, and rigorously training our staff in data protection.

Flat Spring | Clock Spring | Fourslide Spring | Stamping Parts (HS CODE) 732010

Compression Spring (HS CODE)732020

Extension Spring (HS CODE)732020

Torsion Spring (HS CODE)732020

All kinds of wireforms (HS CODE) 732090

Hi there, I am Annie Lin, the key account manager of Zigoal. Contact us to get a free quote and more expertise about custom metal springs and wire forms. Your project will meet a right solution with us.