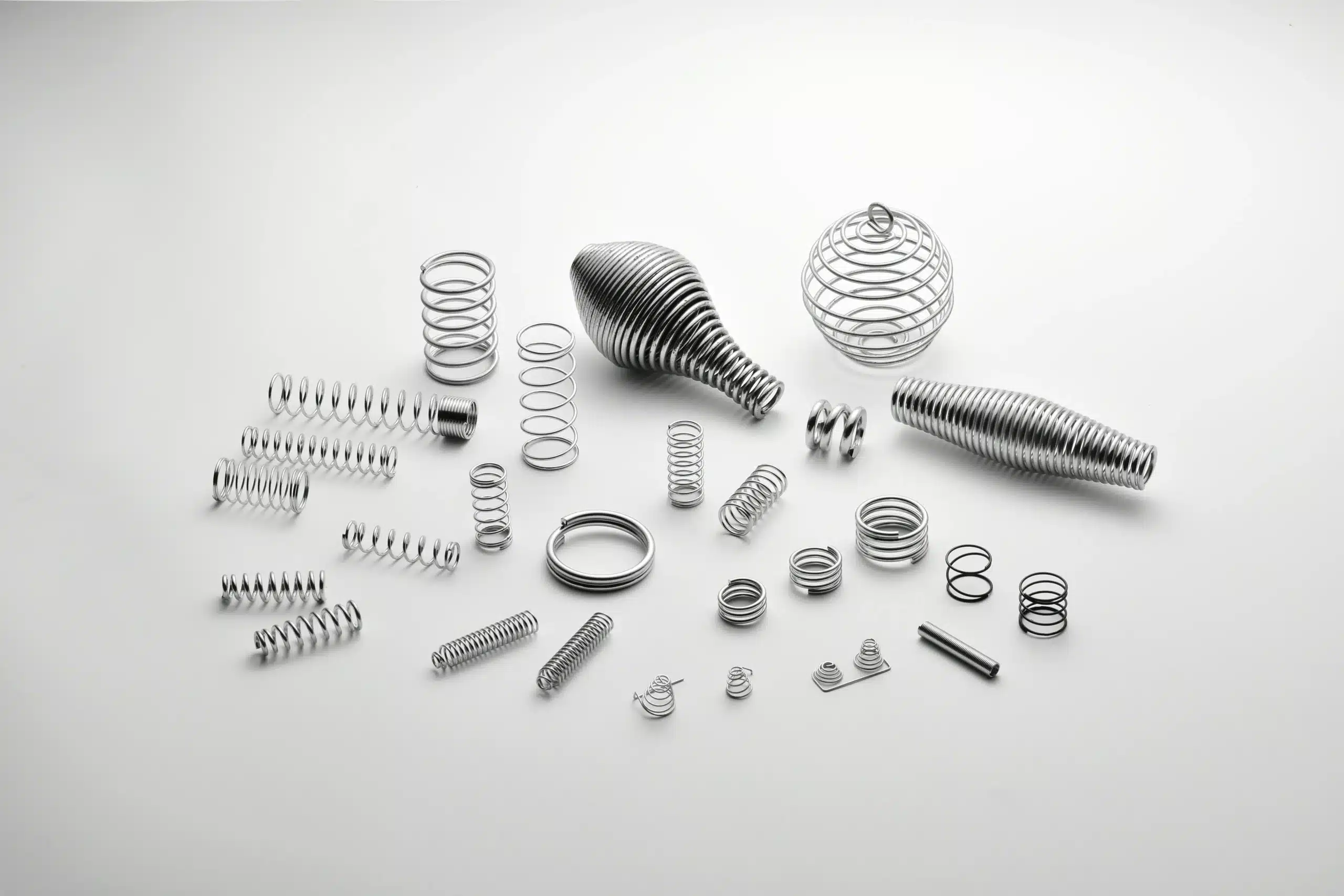

Custom Spring Manufacturer

Each Spring, Experience Zigoal's Quality

High Fatigue Resistance

Offer lasting performance, resisting fatigue under continuous stress

Precision Tolerance

Crafted with tight tolerances for accurate, consistent performance in precision applications

Corrosion-Resistant Coating

Advanced anti-corrosion finishes enhance our springs’ durability in harsh environments

High-strength Materials

Ensuring longevity and resilience in demanding conditions

These Clients Trust in Us

At Zigoal, we pride ourselves on building strong, lasting relationships with our diverse clientele. Our journey over the years has been marked by successful collaborations with a multitude of industries, each with unique demands and high standards.

Capabities

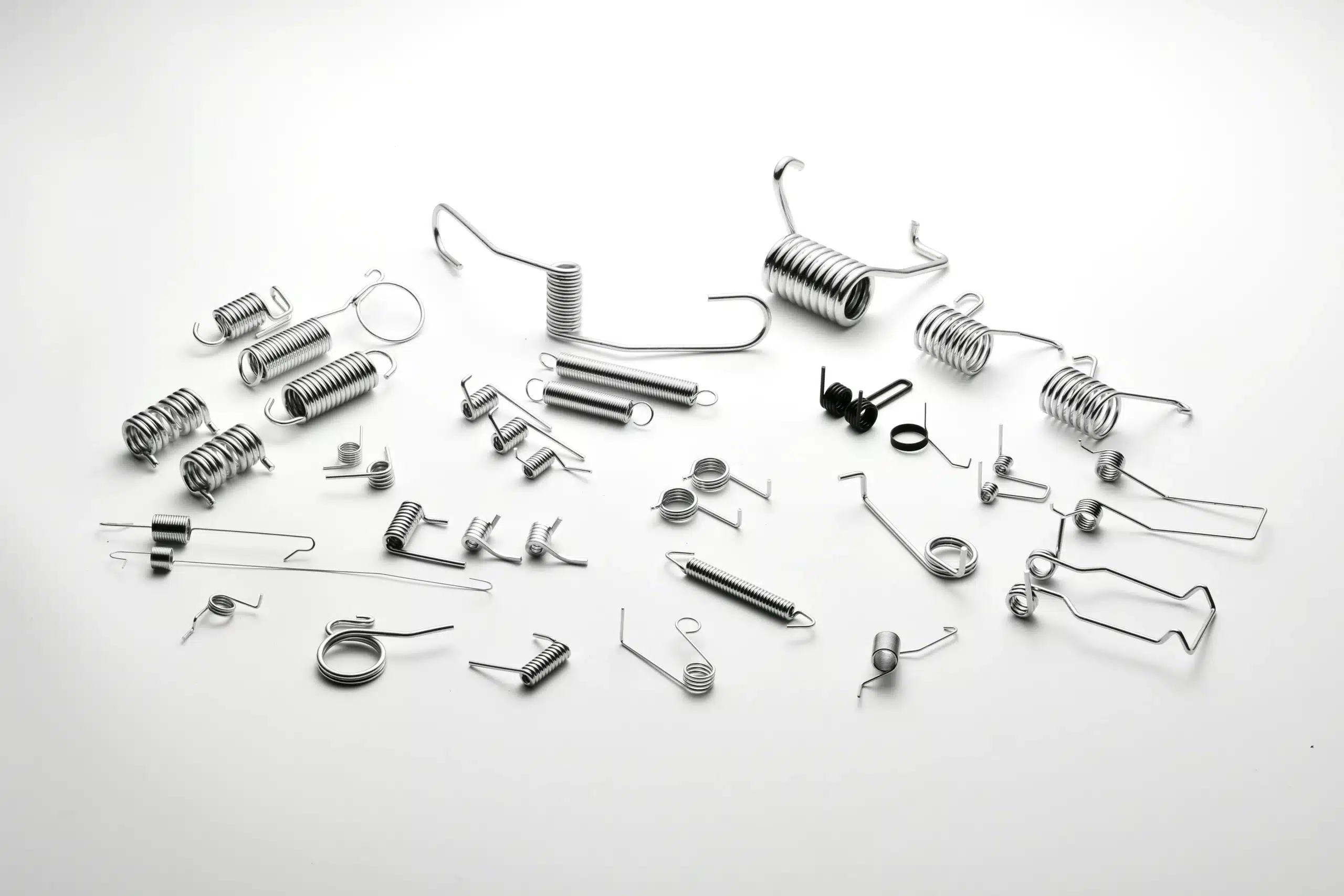

Custom Any Springs and Wire Forms for Your Project

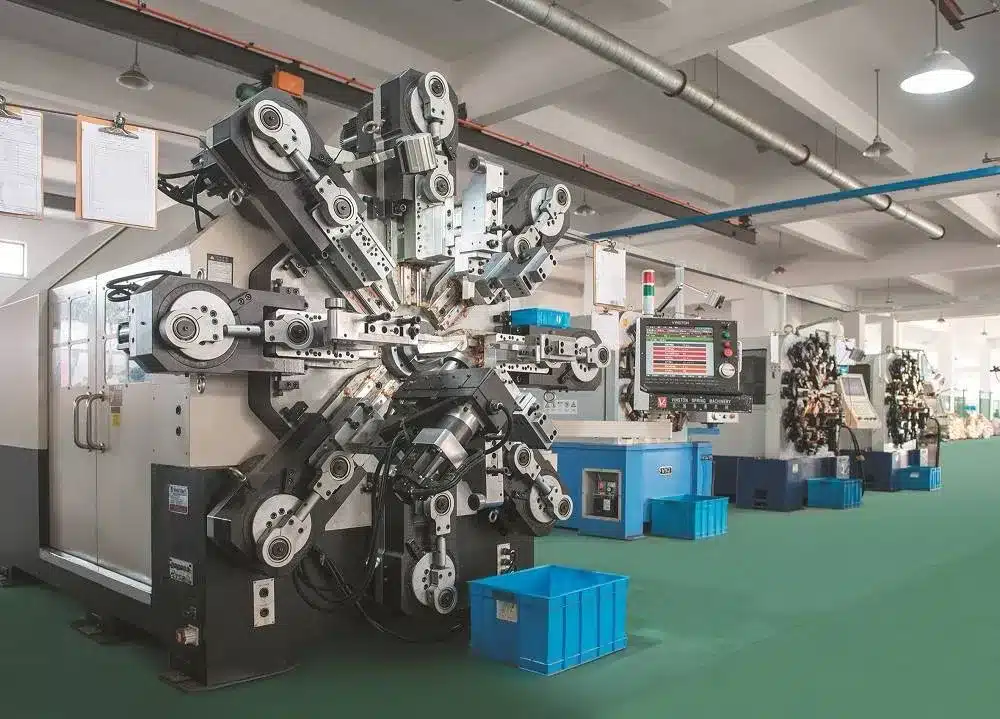

Zigoal offers full capabilities in custom spring and wire forms tailored to your project needs. We can manufacture according to your specific designs, dimensions, material types, surface finishes, and more. Our engineers can customize your orders through a variety of services and processes:

- We utilize precision CNC winding for accurate spring and wire form creation

- Zigoal employs advanced grinding techniques to achieve the perfect surface finish and tolerance

- Zigoal uses state-of-the-art techniques for coiling, bending, and shaping to meet any custom requiremen

- We offer shot peening to enhance fatigue strength

Contact Us Today to Discuss Your Custom Spring and Wire Form Needs!

Material

Material You Can Choose for Your Custom Spring & Wire Forms

Zigoal offers an extensive selection of materials for our custom spring and wire form manufacturing process. Each material is available in various grades and specifications.Ensuring durability, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. Our materials include:

- Carbon Steel

- Music Wire

- Stainless Steel

- Phosphor Bronze

- Alloy Steel

- Beryllium Copper

- Inconel®

- Titanium

- Elgiloy®

- Hastelloy®

Can’t find the material in our listed for your custom manufacturing projects? please reach out to us to discuss how we can meet your needs.

Surface Treatment

Available Surface Finishes for Custom Springs and Wire Forms

Zigoal provides a diverse selection of custom surface finishes to enhance the protection, durability, and aesthetic appeal of your custom springs and wire forms. Each surface finish offers unique benefits tailored to specific applications and environmental conditions. Our surface treatment options include:

- Zinc Plating

- Chrome Plating

- Nickel Plating

- Powder Coating

- Black oxide

- Passivation

- Painting

- Titanium Nitride Coating

- Heat Treatment

- Anodizing

If you have specific requirements for surface finishes,please don’t hesitate to reach out to us!

Rapid Prototyping: Bringing Ideas to Life Quickly

Rapid prototyping is at the core of Zigoal’s manufacturing prowess. It’s about turning concepts into tangible products with speed and precision. Here’s a concise overview:

- Speedy Development: We cut lead times, delivering functional prototypes in days, not months.

- Cutting-Edge Tech: We employ 3D printing and CAD for intricate designs and material versatility.

- Cost-Effective: Our process minimizes waste and keeps projects on budget.

- Client Collaboration: We work closely with you, ensuring a tailored solution.

- Quality Assurance: Stringent testing guarantees top-notch quality.

- Market-Ready: Our prototypes are functional for market testing, easing the transition to mass production

Unlock Cost Savings and Quality

Don’t compromise on quality or budget. Contact us now to find out how our custom wire forms can save you money while maintaining exceptional quality

Applications

Custom Spring Applications Across Industries

Explore the essential role of custom springs across sectors. From household appliances to automotive, aerospace, and electronics, our springs ensure performance and reliability. Discover their impact in various industries, driving innovation and efficiency.

One Stop Solution From Prototyping to Production and Beyond

Your Trusted Custom Wire Forms Manufacturer

As a professional custom wire forms manufacturer in China, we offer a spectrum of services designed to guide you from the initial stages of prototyping to full-scale production, ensuring that your custom spring requirements are met with precision and efficiency.

Our commitment is to provide you with bespoke wire forms solutions tailored to your specific needs, utilizing an extensive range of materials and advanced manufacturing processes.

Why Zigoal is Trusted by 1000+ Clients?

One-stop Custom Solutions

The ability to customize springs to specific requirements is crucial. As an engineer, ensuring that the springs fit the exact specifications of the project is paramount.

Quality and Precision

Quality and precision in manufacturing are crucial for durable, high-performance springs.

Robust Supply Chain Management

Efficient supply chain management ensures timely delivery and consistent product availability, critical for project timelines.

Zigoal can meet tight deadlines

Swift Custom Spring Manufacturing in 5-20Days

Advanced Manufacturing Technology

In-House Plating Facility

Robust Supply Chain

Professional Workforce & Shift Flexibility

With over a decade in the industry, Zigoal adheres to rigorous quality control throughout our manufacturing process, ensuring every spring meets and exceeds industry standards in consistency and performance

Our Quality Control Measures Include:

- In-Process Inspections: Rigorous monitoring during the manufacturing process guarantees consistency in every spring.

- Final Product Checks: Before leaving our factory, each spring undergoes a comprehensive inspection to ensure it meets our exacting standards in terms of dimensions, performance, and resilience.

Certified Quality

Service Global. Precision Engineering. Quality Guaranteed. High Durability. No Failure. Optimal Performance.

Ready to Start Your Custom Spring & Wire Forms Project?

Contact us now to experience unparalleled custom spring &wire forms solutions tailored for your needs.

These Clients Trust in Us

At Zigoal, we pride ourselves on building strong, lasting relationships with our diverse clientele. Our journey over the years has been marked by successful collaborations with a multitude of industries, each with unique demands and high standards.

Working with Zigoal has been a breeze. Their one-stop custom spring solutions have improved our machinery’s efficiency,their expertise and quality are unmatched. And Lily from their team is a pleasure to collaborate with.

In my role as Procurement Director at Tech Solutions, I’ve partnered with Zigoal for years, and their custom springs have always exceeded our expectations. Their expertise and quality are unmatched.

As a Robotics Strategic Project Manager at Global Robotics, I can confidently say that Zigoal’s compression springs have been an integral part of our robotic systems. Peter’s team provided tailored solutions that have been crucial to our success.

Help & Support

Frequently Asked Questions

Clearing the Confusion and Enhancing Customer Satisfaction Efficiency about Custom Spring Manufacturer. Feel free to reach out to our professional team for expert guidance.

Absolutely, our expertise lies in crafting custom springs tailored to your exact requirements. Contact us today to discuss your project.

Our approach to order sizes is flexible, and we’re here to meet your unique needs. Whether you require a small quantity or a larger order, we can accommodate you. Please feel free to get in touch with your specific requirements, and we’ll provide you with the best solution

You can contact our customer service for getting a quote, please provide:

- product dimensions, material type, surface treatment, quantity, and specific requirements

- If available, attach design drawings or samples of the springs. This greatly helps in ensuring precision and meeting your exact requirements.

Surely! You can always request a sample before place the bulk order. Sample time usually will take 2-5 days, depends on the specifications you need. Request a sample now!

Production time depends on the complexity and quantity of your order. We typically complete orders within 5 to 20 days and will provide a specific estimated timeline with your order details.

To place an order, simply reach out to our sales team with your spring specifications and requirements. We’re here to guide you through the process, from initial design consultation to the delivery of your custom springs.

- 30% Advance Fee

to pay 30% of the total cost upfront

- 70% Balance Fee

Complete your balance payment within a certain period before ship out and receive the products you ordered for.

We offer a wide range of materials for spring manufacturing, including High Carbon Steels, Stainless Steels, Copper Alloys, Nickel Alloys, Plastic Composites,Inconel and more.

Material choice depends on the application, including requirements for strength, flexibility, corrosion resistance, and temperature sensitivity.

Zigoal apply a range of finishes and coatings to your custom extension springs, including zinc plating, nickel plating,chrome plating, powder coating, passivation, blacken and more to enhance corrosion resistance, improve conductivity, or meet other specific requirements.

Yes, we are equipped to handle both small and large-scale orders with the same level of precision and efficiency. Our state-of-the-art manufacturing facilities and skilled workforce allow us to meet your needs, regardless of order size.

With over a decade in the industry, Zigoal adheres to rigorous quality control throughout our manufacturing process, including material inspection, dimensional checks, load testing, visual inspection and more to ensuring every spring meets and exceeds industry standards in consistency and performance.

Yes, at Zigoal, we offer door-to-door shipping services for all international orders. You can relax on your sofa while we handle the logistics, ensuring your order arrives directly to your doorstep without any hassle. Our goal is to make receiving your order as easy and convenient as possible, wherever you are in the world.

We ensure the confidentiality of your proprietary designs by signing Non-Disclosure Agreements, employing secure data systems, and rigorously training our staff in data protection.

Compression Spring (HS CODE)732020

Extension Spring (HS CODE)732020

Torsion Spring (HS CODE)732020

All kinds of wireforms (HS CODE) 732090

Flat Spring,Clock Spring,

Fourslide Spring & Stamping Parts

(HS CODE) 732010

Get A Quote Today To Receive Your Custom Sample Within 5 Working Days!

We are here to help you 7 days a week and respond within 24 hours.