Custom Wire Forms Manufacturer

Your trusted partner for custom wire forms, delivering tailored solutions with precision engineering, consistent quality—no matter the complexity!

Looking for custom wire forms for your specific needs?

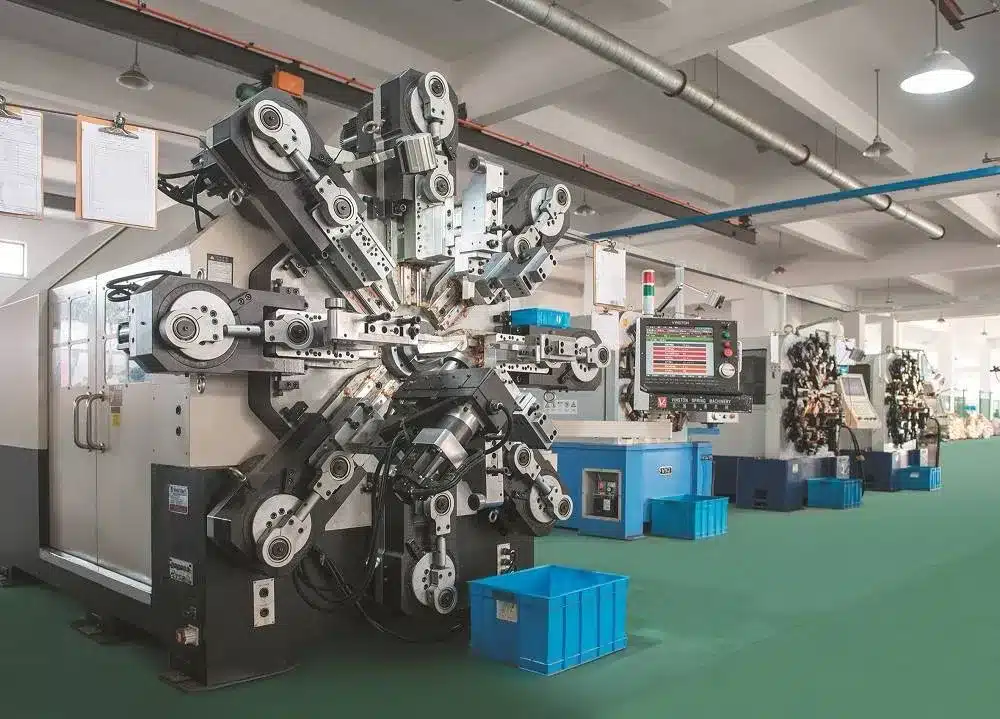

Zigoal Springs: Your Premier wire form manufacturer in the China

We specialize in creating custom wire forms, meticulously designed to meet the highest standards of accuracy and quality for diverse industrial applications. Our commitment to excellence is evident in every aspect of our custom wire forms manufacturing process.

Our Custom Wire Forms Capability:

- .007 to .394Inches(10mm) In Wire Diameter

- RoundWire, Rectangular Wire, Square Wire & Special-Section Wire

- Precision-formed to meet your exact requirements

- Rapid prototyping, high durability, and flexible design options for diverse applications

Why choose our Wire Forms?

High Fatigue Resistance

Offer lasting performance, resisting fatigue under continuous stress

Precision Tolerance

Crafted with tight tolerances for accurate, consistent performance in precision applications

Corrosion-Resistant Coating

Advanced anti-corrosion finishes enhance our wire forms’ durability in harsh environments

High-strength Materials

Ensuring longevity and resilience in demanding conditions

Explore Our Custom Wire Form Types for Industry

Zigoal is a leading manufacturer of custom wire forms, offering a wide range of solutions.Below are just a small selection of the wire forms we have produced, including: bent wire forms, wire hooks, spring clips, clamps,metal hangers,metal stands,brackets, wire formed products and more specialty wire forms. With a commitment to quality and performance, we provide versatile, durable, and customized wire forming tailored for diverse applications, ensuring reliability and excellence in every project.

Wire Spring Latch

Part Names: Hold-down clamp, cover latch, wire form clip, retaining spring clip, filter latch, wire spring latch

Industry: Inlet filters, liquid separators, and vapor condensers for industrial vacuum pumps

Application: Wire form latch fastens top housing to bottom bucket

Material: 0.090” stainless steel 302 wire

Special Features: Two wire form pieces assembled in-line on wire forming machine to create latch

Retainer Clip

Part Names: Stainless steel clip, wire clip, stainless steel retainer clip

Industry: Filters for petroleum, industrial, agricultural, heavy-duty, and biofuel markets

Application: Retainer clip used in vapor control caps on above-ground farm tanks, fuel transfer tanks, and oil tanks

Material: 0.058” stainless steel wire

Special Features: Layer-packed on cardboard sheets to minimize tangling

Metal Hanger Form

Part Names: Metal hanger, wire hanger, stainless steel hanger form

Industry: Construction, industrial assembly, and storage solutions

Application: Supports and organizes cables, wires, or light objects in building and industrial settings

Material: Typically made from galvanized or stainless steel wire

Special Features: Corrosion-resistant coating for durability in various environments

D Ring Wire Form

Part Names: D ring, wire D ring, stainless steel D ring form

Industry: Automotive, marine, aerospace, and outdoor gear manufacturing

Application: Acts as an attachment point for straps, ropes, or cables in securing and fastening systems

Material: 0.125” stainless steel wire or carbon steel

Special Features: Welded for added strength and durability, suitable for heavy-duty applications

S hook Wire Form

Part Names: S hook, wire S hook, metal S hook, S-shaped hook

Industry: Hardware, retail displays, automotive, and industrial applications

Application: Used for hanging or securing items such as tools, cables, chains, or merchandise displays, providing quick and adjustable attachment points

Material: Typically made from stainless steel or galvanized steel wire for corrosion resistance and durability

Special Features: Open-ended design allows for easy installation and removal, customizable sizes and thicknesses to support various load capacities

Spring Hose Clamp

Part Names: Hose clamp, spring clamp, wire hose clamp, tension clamp

Industry: Automotive, plumbing, and HVAC systems

Application: Secures hoses onto fittings, preventing leaks and maintaining pressure in fluid transfer systems

Material: Spring steel or stainless steel for flexibility and corrosion resistance

Special Features: Self-adjusting design provides constant tension, accommodating thermal expansion and contraction

Metal Clamp Wire Form

Part Names: Metal clamp, wire form clamp, wire retaining clip, stainless steel clamp

Industry: Automotive, industrial machinery, electrical installations, and plumbing

Application: Secures pipes, cables, or hoses in fixed positions to prevent movement and minimize wear

Material: Made from stainless steel or galvanized steel wire for strength and corrosion resistance

Special Features: Flexible design allows for easy installation and adjustment, with custom tension options to ensure a secure fit for various diameters

Spring Clip Wire Form

Part Names: Spring clip, wire form clip, tension clip, retaining clip

Industry: Automotive, aerospace, electronics, and industrial equipment

Application: Provides secure holding and retention of components like panels, covers, or connectors, allowing for quick attachment and release

Material: High-carbon steel or stainless steel wire for optimal spring tension and durability

Special Features: Resilient design maintains pressure over time, ensuring a consistent hold even in vibration-prone environments

Precision Wire Forms

Part Names: Precision wire forms, custom wire components, wire formed products, specialty wire shapes

Industry: Automotive, aerospace, medical devices, electronics, and industrial equipment

Application: Used for precise positioning, fastening, and structural support within complex assemblies and mechanisms, including medical devices, electronic connectors, and mechanical assemblies

Material: Crafted from high-grade stainless steel, galvanized steel, or specialty alloys for strength, flexibility, and corrosion resistance

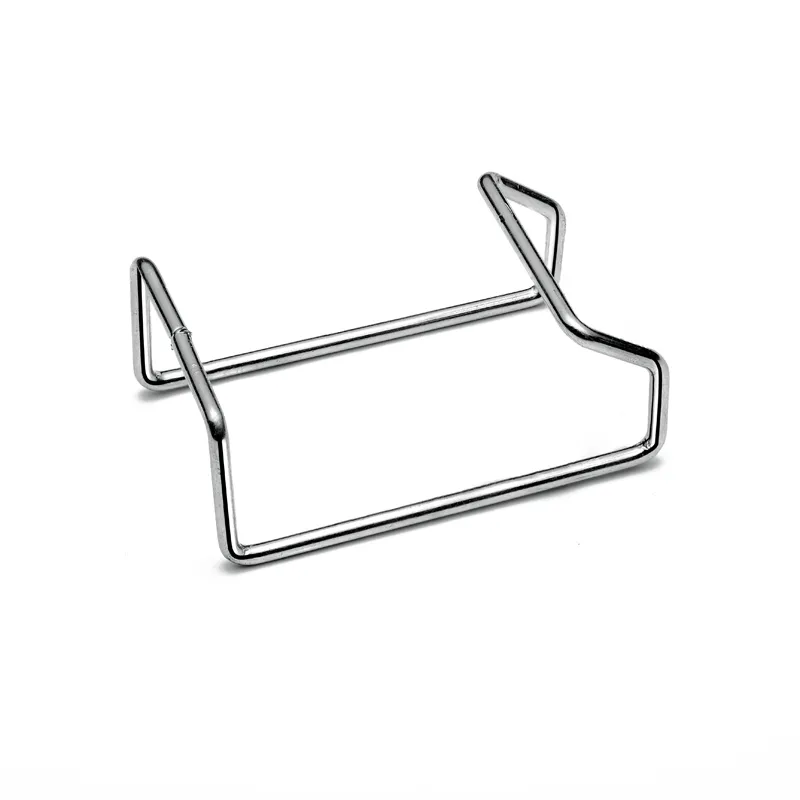

Wire stand Wire Form

Part Names: Wire stand, metal wire form stand, display stand, wire support stand

Industry: Retail displays, electronics, kitchenware, and industrial equipment

Application: Supports and displays items like signage, products, or equipment in a stable, upright position

Material: Typically made from stainless steel or powder-coated steel wire for stability and corrosion resistance

Special Features: Customizable shapes and sizes, lightweight yet durable design, and easy to assemble for portability

custom Metal Hook Wire Form

Part Names: Custom wire hook, metal wire hook, specialty wire form hook

Industry: Retail, industrial manufacturing, automotive, and custom hardware applications

Application: Designed to meet specific hanging, securing, or fastening needs, often used for custom displays, equipment organization, or unique structural supports

Material: Available in stainless steel, galvanized steel, or custom alloy wire for strength and corrosion resistance

Special Features: Fully customizable in shape, size, and thickness to suit exact specifications; durable and easy to install, with options for additional coatings or finishes for enhanced protection

Wire supports

Part Names: Wire supports, wire braces, wire form supports, stabilizing wire forms

Industry: Construction, agriculture, electronics, and industrial machinery

Application: Provides structural support for components like cables, pipes, or panels, ensuring stability and alignment

Material: Stainless steel or galvanized steel wire for durability and resistance to environmental conditions

Special Features: Customizable shapes and lengths to fit various applications, with a strong yet flexible design for easy installation

Link Hook Jack Chain

Part Names: Jack chain, link hook chain, S hook jack chain, wire jack chain

Industry: Lighting fixtures, signage, plumbing, and hardware

Application: Used for suspending light fixtures, signs, or plumbing pipes, providing adjustable length and secure support

Material: Low-carbon steel, stainless steel, or zinc-plated steel for corrosion resistance and durability

Special Features: Flexible design allows for easy adjustments, with open-link construction for adding or removing links as needed

Wire tile

Part Names: Wire tile, wire mesh tile, metal tile support, wire grid tile

Industry: Construction, interior design, architectural installations

Application: Used as a support grid for tiles, or as decorative mesh for ceilings, walls, and partition systems

Material: Typically made from stainless steel, galvanized steel, or aluminum wire for durability and rust resistance

Special Features: Offers structural integrity, easy installation, and customizable patterns for aesthetic or functional applications

Metal Wire Rack

Part Names: Metal wire rack, wire shelving unit, storage wire rack, metal display rack

Industry: Retail, warehousing, kitchen organization, and industrial storage

Application: Provides organized storage with visibility and airflow, ideal for storing kitchen items, retail products, or industrial equipment. Commonly used in environments requiring easy access and sanitary conditions.

Material: Typically made from stainless steel or chrome-plated steel for high durability, rust resistance, and ease of cleaning

Wire Bracket

Part Names: Wire bracket, metal wire bracket, wire support bracket, wire form bracket

Industry: Construction, retail displays, automotive, electrical installations, and furniture assembly

Application: Provides support and mounting for shelves, signs, panels, or electrical components, ensuring stability and alignment

Material: Made from stainless steel or powder-coated steel wire for strength, durability, and corrosion resistance

Special Features: Customizable shapes and sizes, lightweight yet strong, and designed for easy installation in various environments

Hairpin Clip

Part Names: Hairpin clip, R-clip, retaining pin, hitch pin clip, wire hairpin

Industry: Automotive, agriculture, construction, and machinery assembly

Application: Secures shafts, clevis pins, and axles, providing a quick-release mechanism for parts that need easy removal or adjustment

Material: Made from stainless steel or spring steel for resilience and durability

Special Features: Curved design ensures a secure fit with easy insertion and removal, ideal for applications requiring frequent part changes

Bait Snap Clip

Part Names: Bait snap clip, fishing snap, quick snap, lure snap clip

Industry: Fishing, marine, outdoor sports

Application: Provides a quick and secure connection between fishing lines and lures, hooks, or other tackle, allowing for fast changes

Material: Made from stainless steel or corrosion-resistant alloys for strength and durability in saltwater and freshwater environments

Special Features: Easy-to-use snap mechanism, compact design, and strong holding capacity to withstand large fish pulls without compromising line security

Unlock Cost Savings and Quality

Don’t compromise on quality or budget. Contact us now to find out how our custom wire forms can save you money while maintaining exceptional quality

Everything you need to know about Wire Forms

In-Depth Understanding of Wire Forms

What is Wire Forms?

- Wire forms involves shaping and bending wire into specific, often complex configurations using precision machinery. It’s a process of transforming wire into functional, custom shapes for various industrial applications.

Wire Forms Deisgn Considerations

- Tolerance and Precision: Addressing the importance of tight tolerances for high-precision applications.

- Load and Stress Analysis: Ensuring wire forms can withstand the operational stresses and loads.

- Prototyping and Testing: Validating design and functionality through comprehensive testing.

Custom Wire Forming Services

Zigoal’s complex wire forming capabilities extend beyond these methods. Our advanced machinery and skilled team allow us to explore innovative techniques tailored to your unique wire forms project needs.

- Wire Bending

- Swaging (or Winging)

- Wire Threading

- Piercing

- Welding

- Upsetting

- Chamfering

- Grinding

- Coiling

- Laser Cutting

- Forming and Fabrication

- Assembly

Custom Wire Forming Materials

Zigoal custom manufacture wire forms to meet each customer’s precise specifications and tolerance requirements. Our expertise allows us to produce wire products from a variety of materials, ensuring optimal performance for diverse applications. While we can work with almost any material, our most commonly used materials include:

- Stainless Steel: Known for its corrosion resistance and durability, ideal for applications in harsh environments.

- Carbon Steel: Offers excellent strength and rigidity, suitable for heavy-duty applications.

- Music Wire: Provides high tensile strength and is often used for springs and fasteners.

- Aluminum: Lightweight and versatile, perfect for applications requiring reduced weight without sacrificing strength.

- Bronze: Offers excellent wear resistance and is often used in electrical applications.

- Specialty Alloys: Including nickel, titanium, and more, for specific applications requiring unique properties like high temperature or corrosion resistance.

Our team of wire forming experts guides clients in selecting the most appropriate material to ensure optimal performance and longevity of the wire forms.

Wire Forms Surface Treatment Options

- Powder Coating

- Electroplating

- Black Oxide

- Phosphate Coating

- Passivation (Stainless Steel)

- Anodizing (Aluminum Alloys)

- Cadmium Plating

At Zigoal, a custom engineered wire products manufacturer in China, offer a range of surface treatment options to ensure that your wire forms not only perform exceptionally but also meet your aesthetic and environmental requirements.

Custom Wire Form Prototyping

Rapid prototyping is at the core of Zigoal’s manufacturing prowess. It’s about turning concepts into tangible products with speed and precision. Here’s a concise overview:

- Speedy Development: We cut lead times, delivering functional prototypes in days, not months.

- Cutting-Edge Tech: We employ 3D printing and CAD for intricate designs and material versatility.

- Cost-Effective: Our process minimizes waste and keeps projects on budget.

- Client Collaboration: We work closely with you, ensuring a tailored solution.

- Quality Assurance: Stringent testing guarantees top-notch quality.

- Market-Ready: Our prototypes are functional for market testing, easing the transition to mass production.

Exploring the Diverse Industries We Serve with Custom Wire Forms Solutions

Our custom cnc wire forming are engineered to meet the unique needs of various industries, from automotive to medical, electronics, and beyond. By leveraging precision manufacturing techniques, we create wire forms that enhance product functionality and reliability. Our commitment to quality and innovation enables us to support our clients’ success across a wide spectrum of applications.

Wire Forms in Automotive Engineering: Fueling Innovation and Performance

Explore how custom wire forms are crucial in the automotive industry, enhancing vehicle structure and function. They offer strength, flexibility, and precision in engine components and suspension systems, driving innovations in design and manufacturing for improved safety, performance, and efficiency.

Forming Springs in Puzzle IQ Games: Crafting Complexity and Creativity

Dive into how our custom forming springs in puzzle IQ games challenge and engage the mind with their complex designs. These puzzles enhance spatial reasoning, fine motor skills, and creativity, providing a stimulating and educational experience.

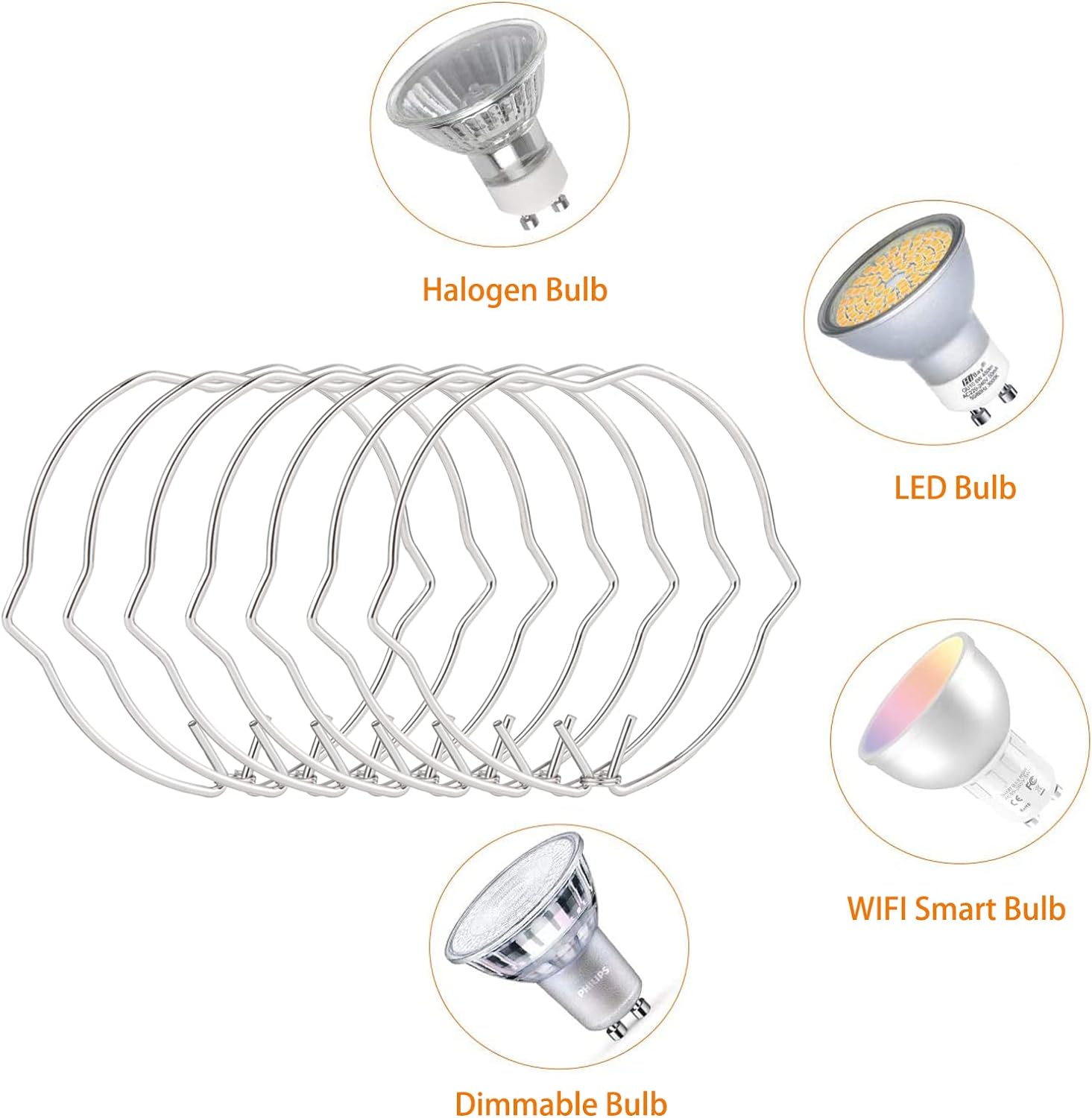

Custom Spring Clip Solutions for LED Lighting: Enhancing Installation Precision and Stability

Explore how custom spring clips revolutionize LED light installations by ensuring precision and reliability. These clips offer a secure fit for LED lights, facilitating stable and seamless integration into any setting, and their adaptability enhances both functionality and design.

Custom Wire Rack Innovations for Perfect Pancake Presentation

Explore how custom wire racks for pancakes improve cooling, storage, and serving. Their design allows for efficient air circulation, keeping pancakes warm and textured. Ideal for breakfast setups, they ensure a neat presentation and reduce clutter.

Metal Hooks for Kitchen Efficiency: Transforming Space into Storage

Discover the utility of custom S hooks in kitchens for organizing utensils and cookware, transforming unused space into practical storage. Their straightforward design simplifies installation and adjustment, streamlining kitchen organization and accessibility.

Simple 3 Steps to Custom spring forms

Send Your Inquiry

Fill out our contact form with your details and attach relevant drawings or specifications for your custom wire forming.

Sample and Production

We create a prototype of your customized wireform for approval and initiate manufacturing upon your confirmation that it meets all specifications

Parts are Shipped!

Zigoal's state-of-the-art digital manufacturing process ensures rapid production with turnaround times as fast as few days

Each Spring Need Strict Quality Control

With over a decade in the industry, Zigoal adheres to rigorous quality control throughout our manufacturing process, ensuring every wire forms meets and exceeds industry standards in consistency and performance

Our Quality Control Measures Include:

- In-Process Inspections: Rigorous monitoring during the manufacturing process guarantees consistency in every spring.

- Final Product Checks: Before leaving our factory, each spring undergoes a comprehensive inspection to ensure it meets our exacting standards in terms of dimensions, performance, and resilience.

Guarantee Manufacturing & Shipping Time

To guarantee manufacturing and shipping times, Zigoal offers precise and on-time production with efficient logistics, ensuring your orders arrive as promised.

Manufacturing Time: 7-20 Days

Zigoal Springs offers rapid custom spring production through advanced machinery, robust material resources, in-house plating, skilled labor, and efficient processes for fast, reliable deliveries.

Loading Time: 1 Day

Springs are strategically and securely loaded into containers, ensuring minimal movement and maximum safety during transit.

Testing&Packaging time: 3 days

We conduct thorough inspections for accuracy, strength, and surface quality, followed by customized, secure packaging to ensure the springs are ready for safe transit.

Shipping Time: 15-35 Days

We handle all shipping aspects, including preparation of custom clearance documents and efficient logistics coordination, providing real-time tracking for timely and transparent delivery.

Our Happy Clients Say

At Zigoal, we pride ourselves on building strong, lasting relationships with our diverse clientele. Our journey over the years has been marked by successful collaborations with a multitude of industries, each with unique demands and high standards.

Working with Zigoal has been a breeze. Their one-stop custom spring solutions have improved our machinery’s efficiency,their expertise and quality are unmatched. And Lily from their team is a pleasure to collaborate with.

In my role as Procurement Director at Tech Solutions, I’ve partnered with Zigoal for years, and their custom springs have always exceeded our expectations. Their expertise and quality are unmatched.

As a Robotics Strategic Project Manager at Global Robotics, I can confidently say that Zigoal’s compression springs have been an integral part of our robotic systems. Peter’s team provided tailored solutions that have been crucial to our success.

Frequently Asked Questions

Clearing the Confusion and Enhancing Customer Satisfaction Efficiency about Custom Wire Forms Manufacturer China. Feel free to reach out to our professional team for expert guidance.

Absolutely, our expertise lies in crafting custom wire forms tailored to your exact requirements. Contact us today to discuss your project.

At Zigoal, we understand that every project is unique. We offer flexible minimum order quantities tailored to your project’s needs, ensuring you receive the quality and quantity you require without unnecessary excess. Please feel free to get in touch with your specific requirements, and we’ll provide you with the best solution

Getting a quote is easy and straightforward. Simply contact us with:

- product dimensions, material type, surface treatment, quantity, and specific requirements.

- If available, attach design drawings or samples of the wire forms. This greatly helps in ensuring precision and meeting your exact requirements.

Our team will review your information and provide you with a detailed quote as quickly as possible.

Surely! You can always request a sample before place the bulk order. Sample time usually will take 2-5 days, depends on the specifications you need. Request a sample now!

Absolutely! Our team of experienced engineers is here to assist you from concept through to creation. If you have an idea, we can work with you to design, prototype, and manufacture the perfect wire form for your needs.

When selecting materials for wire forms, several options are available, each with unique properties that make them suitable for different applications. Here’s an overview of the best-suited materials:

| Material | Key Properties | Common Applications |

|---|---|---|

| Stainless Steel | High strength, durable, corrosion-resistant | Automotive, aerospace |

| Aluminum | Lightweight, malleable, corrosion-resistant | Lightweight structures |

| Copper | Excellent conductivity, flexible | Electrical components |

| Brass | Corrosion-resistant, strong | Decorative items |

| Nickel | Corrosion-resistant, extreme temperature tolerance | Moisture-prone environments |

| Titanium | Strongest metal, corrosion-resistant | Aerospace components |

| Carbon Steel | High tensile strength, affordable | Sturdy wire forms |

Choosing the right material depends on the specific requirements of the application, including mechanical properties, environmental exposure, weight considerations, and budget constraints.

Need help selecting the right material? Contact our experts for personalized guidance and ensure your wire form meets all performance and budget requirements!

Quality is at the heart of everything we do. We employ rigorous quality control processes throughout manufacturing, including material inspection, in-process quality checks, and final product testing. Our commitment to quality ensures that your custom wire forms meet or exceed industry standards.

- 30% Advance Fee

to pay 30% of the total cost upfront

- 70% Balance Fee

Complete your balance payment within a certain period before ship out and receive the products you ordered for.

Production time depends on the complexity and quantity of your order. We typically complete orders within 10 to 20 days. However, we strive to offer some of the shortest lead times in the industry while maintaining our high-quality standards. Please contact us with your project details for a more accurate estimate.

Hi there, I am Annie Lin, the key account manager of Zigoal. Contact us to get a free quote and more expertise about custom metal springs and wire forms. Your project will meet a right solution with us.