This article delves into the prototyping process of double torsion springs, detailing the materials and steel used, a crucial phase in spring manufacturing with the shaft. We explore the essential steps from design and rapid prototyping techniques to rigorous testing and final adjustments in manufacturing, ensuring the development of high-performance and reliable steel springs and shaft materials.

Initial Considerations Before Prototyping Double Torsion Springs

When manufacturing double torsion springs from wire, it’s crucial to follow a structured approach to ensure the custom final product meets the specific needs of the application. Here are some key considerations to take into account:

-

Application Requirements

-

Understanding the Application: It’s essential to have a comprehensive understanding of the application for which the torsion spring is designed. This includes the operational role of the spring, the mechanical loads it will encounter, and any dynamic forces it must withstand.

-

Load Requirements: Determine the torque requirements and any variations in loading that the spring will need to accommodate during its service life. This assessment helps in specifying the necessary strength and durability of the spring.

-

Environmental Conditions: Analyze the environmental factors such as temperature, humidity, and exposure to chemicals or corrosive elements. These conditions can significantly impact the material choice and design of the spring.

-

Space Constraints: Consider the available space in the application where the spring will be installed. This influences the overall dimensions and configuration of the spring, including the need for compact designs where space is limited.

-

-

Material Selection

-

Overview of Common Materials: Double torsion springs are typically made from high-carbon steel, stainless steel, or alloy steels like chrome silicon. Each material offers different properties in terms of strength, flexibility, and resistance to environmental factors.

-

Criteria for Material Selection:

-

Strength and Durability: Choose a material that can withstand the mechanical stresses and strains expected in the application.

-

Corrosion Resistance: For applications exposed to harsh environments, materials with higher corrosion resistance such as stainless steel or coated metals are preferable.

-

Temperature Resistance: Consider materials that maintain their mechanical properties across the expected temperature range of the application.

-

-

-

Design Specifications

-

Wire Diameter: The thickness of the wire used in the torsion spring affects its strength and flexibility. Thicker wires increase the load capacity but decrease flexibility.

-

Coil Diameter: The diameter of the coils determines the rotational leverage that the spring can exert. A larger coil diameter allows for higher torque at lower rotational speeds.

-

Leg Configuration: The design of the spring legs (e.g., straight, bent, or looped) influences how the spring connects to other components and how it transfers load.

-

Spring Rate: This parameter indicates the amount of load required to twist the spring by a unit angle. It is crucial for ensuring that the spring provides the necessary performance without overloading or failing prematurely.

-

Designing a Double Torsion Spring

Creating an effective double torsion spring and custom springs requires a meticulous design process, leveraging the right tools and expertise in torsional springs. Here’s a structured approach to designing these springs:

-

Step-by-Step Design Process

-

Initial Specification: Define the operational requirements, including torque needs, space constraints, and environmental conditions. This step sets the groundwork for all subsequent design choices.

-

Calculations for Torque:

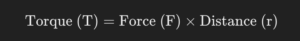

where force is measured in newtons (N) and distance is the perpendicular distance from the pivot point, in meters (m). Torque is measured in newton-meters (Nm). - Torque can be calculated using the formula:

T=K×θ

where T is the torque, K is the spring constant, and θ is the angle of twist. This formula helps determine the spring characteristics needed to meet specific load requirements in applications like extension springs. - The formula T=K×θT = K \times \thetaT=K×θ calculates torque, where TTT is the torque, KKK is the spring constant, and θ\thetaθ is the angle of twist. This calculation helps in determining the required spring characteristics to meet specific load requirements in mechanical applications.

-

Spring Rate Calculation: Calculate the spring rate using \( K = \frac{d^4G}{8D^3n} \), where \( d \) is the wire diameter, \( G \) is the modulus of rigidity, \( D \) is the mean coil diameter, and \( n \) is the number of active coils. This formula helps in determining how stiff the spring needs to be.

-

Stress Analysis: Analyze the stresses using \( \sigma = \frac{32TD}{\pi d^3} \), where \( \sigma \) is the stress, \( T \) is the torque, \( D \) is the coil diameter, and \( d \) is the wire diameter. This step is critical for ensuring that the spring will not fail under expected loads.

-

Prototyping and Testing: After calculating and designing, produce a prototype to test the spring under real conditions to ensure it meets the designed specifications.

-

-

-

Consulting with Engineers

-

Collaboration Importance: Collaborating with experienced spring engineers or specialists is essential during the design phase. These professionals can provide valuable insights into material selection, load capacities, and potential design flaws.

-

Technical Review: Having a specialist review the designs can help ensure that all aspects of the spring’s functionality are optimized. This can prevent costly redesigns and ensure the spring performs as expected in its application.

-

By following these steps and utilizing the right tools and expertise, you can design custom torsional springs that meet all necessary specifications and perform reliably in their intended application. This meticulous approach to design, backed by expert consultation on torsion and advanced simulation tools, is key to developing high-performance custom springs.

Prototyping Process for Double Torsion Springs

The prototyping process is a critical phase in the development of double torsion springs, allowing for the verification of design specifications and functional testing before full-scale production. Here’s a comprehensive look at this process:

-

Rapid Prototyping Techniques

-

3D Printing: While traditional 3D printing materials may not always meet the mechanical demands for final spring applications, 3D printing can be invaluable for creating precise geometric models of the spring for shape and fitment testing, particularly in complex assemblies.

-

CNC Machining: CNC machining is often used for creating prototypes of springs from the actual material that will be used in production. This method is highly accurate and can produce close-to-final specifications, which is essential for functional testing.

-

-

From Design to Prototype

-

Material Preparation: Select the appropriate spring material based on the design requirements, such as stainless steel or high-carbon steel, and prepare it in the form of wire with the specified diameter.

-

Coiling: The prepared wire is fed into a CNC spring coiler, which bends and twists the wire into the desired coil shape according to the design specifications. This step is crucial for ensuring the spring’s functionality in terms of torque and flexibility.

-

Forming: The legs of the torsion spring are then formed to meet the specific attachment points and operational requirements of the application. This might involve bending the legs into hooks, loops, or other configurations as needed.

-

Heat Treating: Often, the prototype will undergo a heat-treating process to enhance its mechanical properties, such as tensile strength and durability. This step is particularly important for ensuring that the spring can withstand the stresses of operation.

-

Testing and Optimization of Double Torsion Springs

Testing and optimization are crucial stages in the development of double torsion springs, ensuring that the final product meets or exceeds the design requirements. Here’s an outline of the process:

-

Testing Protocols

-

Set-Up: Establish a testing environment that mimics the operational conditions the spring will face. This includes mounting the spring in a rig that can apply and measure torsional loads, and, if necessary, simulate environmental conditions like temperature variations or corrosive atmospheres.

-

Load and Fatigue Testing: Conduct cyclic loading tests to determine the endurance of the spring under repeated stress. This helps in assessing the life expectancy of the spring and its performance degradation over time.

-

Torque and Deflection Tests: Measure the torque required to achieve specific angular deflections. This testing is crucial for verifying that the spring meets the mechanical requirements specified in the design.

-

Environmental Testing: If applicable, expose the spring to various environmental conditions to evaluate its resistance to factors like temperature extremes, humidity, and corrosion.

-

-

Analyzing Test Results

-

Data Collection and Analysis: Gather detailed measurements from testing, including load capacities, deflections, and any failures. Use statistical tools to analyze the data, identifying performance trends and potential outliers.

-

Performance vs. Specifications: Compare the test results against the design specifications. Look for any discrepancies and assess whether they are within acceptable tolerance limits.

-

Identifying Areas for Improvement: Focus on areas where the prototype fails to meet the expectations or specifications. Determine if the shortcomings are due to material choice, design dimensions, or manufacturing processes.

-

-

Iterative Design and Prototyping

-

Feedback Loop: Integrate the insights gained from testing back into the design process. This iterative approach allows for continuous improvements, enhancing the spring’s performance with each prototype iteration.

-

Design Adjustments: Make necessary modifications to the design parameters, such as adjusting wire diameter, coil diameter, or leg configurations, based on the test results. These adjustments might also involve changing the material or the manufacturing technique.

-

Retesting: After making design changes, produce a new prototype and subject it to the same rigorous testing protocols. This cycle of design, test, analyze, and redesign is repeated until the prototype satisfactorily meets all design specifications and performance criteria.

-

This rigorous testing and optimization process ensures that the double torsion springs are not only compliant with technical specifications but are also optimized for durability and performance in their intended applications. By embracing an iterative design philosophy, manufacturers of traditional torsion spring manufacturing can achieve high-quality, reliable products like double torsion spring designs and industrial torsion springs tailored to specific customer needs, including hinged torsion springs.

Finalizing the Prototype for Double Torsion Springs

Finalizing a prototype involves refining the design of custom torsion springs to ensure it is ready for mass production, including part torsion spring and torsion spring designs. This stage is critical for transforming a well-tested prototype into a production-ready product. Here’s how to approach this crucial phase:

-

Final Adjustments

-

Incorporate Test Feedback: Integrate all the feedback and data gathered from the extensive testing phases. Focus on making final modifications that address any remaining performance issues or discrepancies with design specifications.

-

Optimize Design for Manufacturability: Adjust the design to simplify manufacturing processes, reduce costs, and enhance product reliability. This might include altering features that are difficult to produce or that do not contribute significantly to the spring’s functionality.

-

Consultation with Engineers: Collaborate with manufacturing and design engineers to ensure that the changes are feasible and that they will not introduce new issues in the production phase.

-

-

Preparing for Production

-

Final Material Selection: Confirm the material choices based on performance, cost, availability, and compliance with industry standards. Ensure that the selected materials have been proven effective in the testing phase and are suitable for large-scale manufacturing.

-

Specifying Manufacturing Tolerances: Define precise manufacturing tolerances to ensure high-quality production. Tolerances should be tight enough to ensure functional reliability but allow for efficient production without excessive cost.

-

Tooling and Equipment Setup: Design and prepare the necessary tooling and equipment for production. This may include custom jigs, fixtures, and dies needed for efficient and consistent manufacturing of the springs.

-

Pilot Run: Conduct a pilot production run to test the manufacturing process with the final design. This step is crucial for identifying any potential issues in the production line that were not evident during prototyping.

-

Quality Assurance Protocols: Establish rigorous quality assurance checks to be performed during production. These protocols should include inspections and testing of the springs to ensure they meet all defined specifications and quality standards.

-

Conclusion

Prototyping is essential in developing reliable and efficient double torsion springs, ensuring each design meets functional and operational standards. Engaging with professionals and utilizing advanced tools like CAD and FEA significantly enhances the outcomes for double torsion springs, optimizing the spring’s performance.

Begin your prototyping journey with Zigoal Spring today. Embrace thorough design, meticulous testing, and careful optimization to craft successful double torsion spring applications.